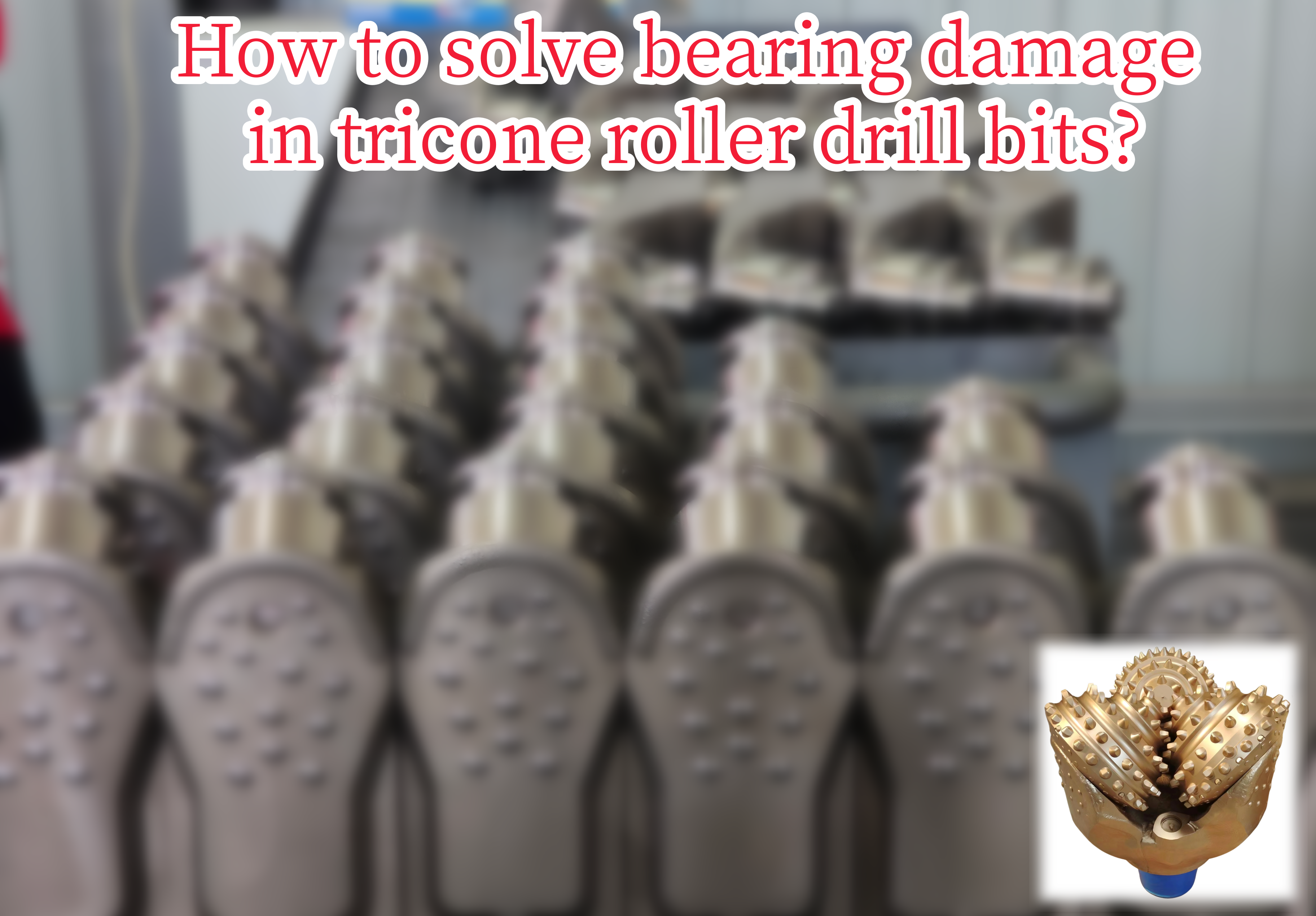

How to Solve the Bearing Damage in Tricone Bit?

As a core component of oil and gas drilling and trenchless engineering equipment, the bearing is the "heart" of the tricone drill bit. However, it often fails prematurely due to extreme downhole conditions, becoming a key pain point restricting drilling efficiency.

There are three core reasons for bearing damage:

First, high impact loads and alternating stresses downhole. The radial runout and axial extrusion of the cone during drilling can easily cause fatigue spalling of the bearing raceway;

Second, invasion of drilling fluid and cuttings. Traditional seals cannot isolate impurities effectively, leading to abrasive wear of the bearing; third, lubrication failure. In high-temperature and high-pressure environments, lubricating grease is easily diluted or carbonized, losing its protective effect.

To address these pain points, Drillmore has developed three targeted core technologies to comprehensively improve bearing quality.

First, we adopt a carburizing strengthening process for high-carbon chromium bearing steel, which increases the surface hardness of the bearing to above HRC62 while maintaining the toughness of the core, achieving dual improvement in impact resistance and wear resistance.

Second, we have innovated a multi-channel labyrinth seal + high-pressure lubrication integrated system, which effectively isolates drilling fluid invasion and continuously supplements high-temperature lubricating grease to avoid lubrication failure.

Third, we have optimized the spherical roller bearing structure to evenly distribute the load across the entire raceway and reduce local stress concentration.

Your email address will not be published. Required fields are marked with *