Nhọrọ ịkwọ ụgbọ mmiri kacha mma

Chọgharịa Otu Ngwaahịa

3.4k

Otu ọkachamara ọkachamara

Injinia na onye ọrụ aka na-ahazi ihe ziri ezi maka nsogbu abrasion.

25+

R&D

Anyị na-aga n'ihu na-emeziwanye sistemụ anyị hụ na ihe ndị dị ugbu a kwụsiri ike ma na-atụ aro ngwakọta ọhụrụ iji dabara nsogbu abrasion ọhụrụ.

18+

N'ozi saịtị dị

Nkwado teknụzụ 7x24h na anyị na-ewere 100% ọrụ na nsogbu anyị

5.9%

Ndị ọrụ nlekọta ndị ahịa

Nka na ụzụ & azụmahịa otu na-esochi arịrịọ ọ bụla na onye ndụmọdụ ma ọ bụ sample ma ọ bụ mbupu.

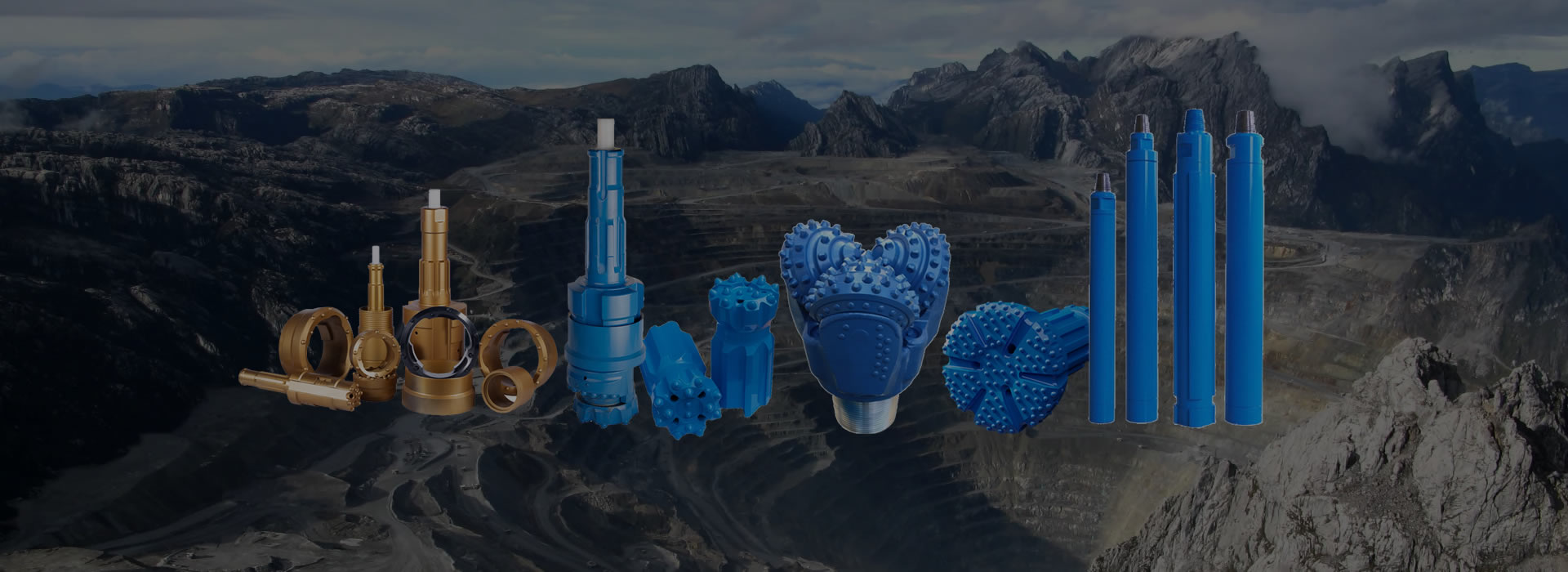

Anyị na-enye ngwa ịkwọ ụgbọ mmiri na-adịgide adịgide

Ọrụ ọkachamara

Ọrụ ọkachamara

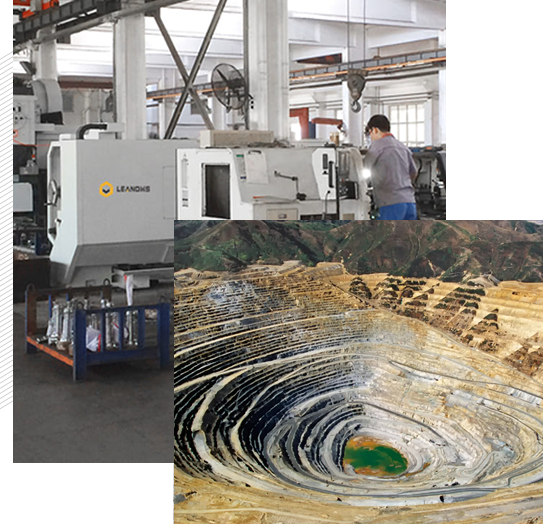

DrillMore Rock Tools Company ejirila ụlọ ọrụ na-egwupụta ihe karịrị afọ 30. Anyị bụ ọkachamara n'ichepụta, mmepe, nrụpụta na ọrụ nke tricone bits, ngwaọrụ DTH, Ngwa Hammer kacha elu, PDC Bits maka Ngwuputa, Ngwupu ala ọma, mkpọpu ala geothermal, Mwube, Tunneling, Quarrying...

- Onye na-eweta ọkachamara

Maka Drilling IndustrialỌrụ ndị ahịa pụrụiche - Nhazi dị elu

Njikwa ogo siri ikeTinye uche na asọmpi

Akụkọ kacha ọhụrụ & mmelite