Roller Cone Bits: HDD Guided vs. Vertical Shaft Differences

In the field of drilling equipment, roller cone bits are the core components for rock breaking and drilling. However, despite both being roller cone bits, the guided roller cone bits specifically designed for Horizontal Directional Drilling (HDD) and those used for vertical shaft (vertical well/mining shaft) construction are vastly different in structural design and appearance due to the essential differences in their adapted working conditions. For drilling practitioners and purchasers, understanding these differences not only enables quick selection to avoid pitfalls but also deepens the comprehension of the industry's core logic of "equipment adapting to working conditions". Today, we will break down the differences between the two from the two key dimensions of structure and appearance.

I. HDD Guided Roller Cone Bits: Born for "Flexible Steering", Compact in Structure & Appearance

The core requirement of HDD construction is "precision steering and curved drilling". For example, in municipal pipeline laying, the drill bit needs to bypass underground obstacles and follow the designed trajectory. This working condition determines that the structure and appearance of guided roller cone bits must be centered around "flexibility and controllability".

In terms of structure, the core design highlights of guided roller cone bits are "compactness + steering empowerment". Most adopt a 3-roller cone layout, but the roller cones are arranged more densely and compactly overall. Some models are designed with an eccentric roller cone layout, which can easily generate lateral force when matched with a steering motor to achieve trajectory fine-tuning. The bearing system is its core force-bearing component, adopting lateral force-resistant sealed bearings with a slightly longer axial length and smaller outer diameter, which can cope with alternating loads caused by frequent steering and avoid bearing cracking or jamming. Most importantly, 1-2 guide plates (guide wings) are integrated on the side or back of the drill bit, made of high-wear-resistant cemented carbide, which can not only fit the hole wall to stabilize the direction but also reduce shaking during drilling. The tooth design focuses on "wear resistance and adaptability", mostly short and thick milled teeth (steel teeth) or small-sized inserted teeth, with a tooth height of 3-8mm and dense tooth spacing, suitable for scraping and grinding formations such as clay, sand, weathered rock. The flow channel design is also extremely simple, with 1-2 large-diameter water eyes, giving priority to ensuring cuttings discharge and preventing blockage.

In terms of appearance, guided roller cone bits are highly recognizable. Overall, they are in the shape of a "slender rod" with a large ratio of total length to diameter, and the common diameter range is 150-400mm. This shape allows the drill bit to turn flexibly in curved hole sections without jamming. The protruding guide plates on the side are the most intuitive identifier; the drill bit end face is flat, with no obvious nozzle holes, only simple flow channel grooves. The surface is mostly sprayed with a light gray or yellow wear-resistant coating, which is relatively thin. Product markings clearly indicate "guided type", "HDD special use" and curvature radius and other parameters for quick identification.

II. Vertical Shaft Roller Cone Bits: Born for "High-Pressure Rock Breaking", Thick and Solid in Structure & Appearance

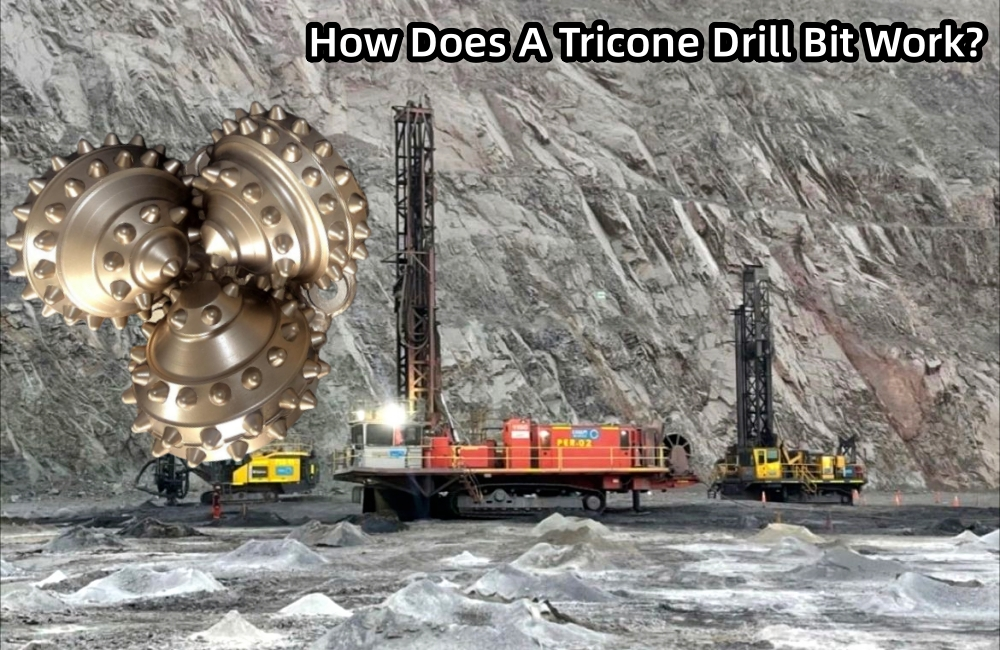

The core requirement of vertical shaft construction (such as mining shafts and oil well vertical wells) is "efficient rock breaking and bearing high drilling pressure". The drilling trajectory is mainly vertical, and the requirement for steering flexibility is relatively low. This working condition determines that the structure and appearance of vertical shaft roller cone bits must be built around "sturdiness and efficiency".

In terms of structure, the core design of vertical shaft roller cone bits is "strengthening load-bearing + improving rock-breaking capacity". Most adopt 3 roller cones (large-diameter models can reach 4 roller cones), with the roller cones arranged in a centrally symmetrical layout. The roller cones have a larger diameter and wider tooth ring width, and the roller cone shaft has extremely high rigidity, which can bear tens of tons of axial drilling pressure. The bearing system adopts a composite structure of heavy-duty roller bearings + floating bearings, with a thick radial thickness and outstanding impact resistance, which can cope with severe vibrations during hard rock breaking. The biggest difference from guided drill bits is the absence of a steering structure; the drill bit body is of a solid and thick design, focusing fully on rock breaking. The teeth are divided into milled teeth and large-sized inserted teeth. The milled teeth are 10-15mm in height with sharp tooth tips, and the inserted teeth adopt 8-12mm large-grain cemented carbide, with a conical or wedge-shaped tooth profile, which smashes hard rock by impact force. The flow channel design is more complex, with 3-6 high-pressure nozzles distributed on the end face, which can spray high-pressure drilling fluid to cool components and discharge cuttings in a timely manner.

In terms of appearance, the first impression of vertical shaft roller cone bits is "short, fat and sturdy", with a small ratio of total length to diameter, and a diameter range of 200-600mm or more. Large-diameter models are similar to thick metal discs, full of a sense of power. The 3 roller cones have a large exposed area, with sharp and protruding teeth, and multiple circular nozzle holes on the end face are clearly visible. Some models are equipped with red or black transportation protective caps. The surface is sprayed with a thick dark gray or black wear-resistant coating, which is impact-resistant and corrosion-resistant. Product markings will indicate key parameters such as "vertical shaft special use", "hard rock type" and "drilling pressure level", highlighting its load-bearing and rock-breaking properties.

Core Difference Summary: Working Conditions Determine Form

Simply put, guided roller cone bits are "exquisite steering experts", focusing on steering and lateral force resistance in structure, with a slender appearance and guide plates; vertical shaft roller cone bits are "sturdy rock-breaking giants", focusing on load-bearing and efficient rock breaking in structure, with a short, fat appearance and multiple nozzles. The differences between the two are essentially the embodiment of differentiated product design driven by differences in drilling working conditions. Mastering these structural and appearance identification points can make on-site construction inspection, equipment procurement and selection, as well as industry knowledge popularization more efficient and accurate.

RELATED NEWS

Send a Message

Your email address will not be published. Required fields are marked with *