Pilihan Pangeboran Pangalusna Anjeun

Kotektak Kategori Produk

3.4k

TIM PROFESIONAL

Insinyur sareng teknisi ngatur bahan anu leres pikeun masalah abrasion.

25+

Urang Sunda

Urang terus ningkatkeun sistem kami mastikeun kualitas stabil bahan ayeuna jeung nyarankeun komposit anyar pikeun nyocogkeun masalah abrasion anyar.

18+

ON SITE LAYANAN sadia

7x24h rojongan teknis na urang nyandak 100% tanggung jawab dina masalah urang

5.9%

Palayanan palanggan

Tim téknis & komérsial nuturkeun unggal pamundut ngeunaan konsultan atanapi conto atanapi kiriman.

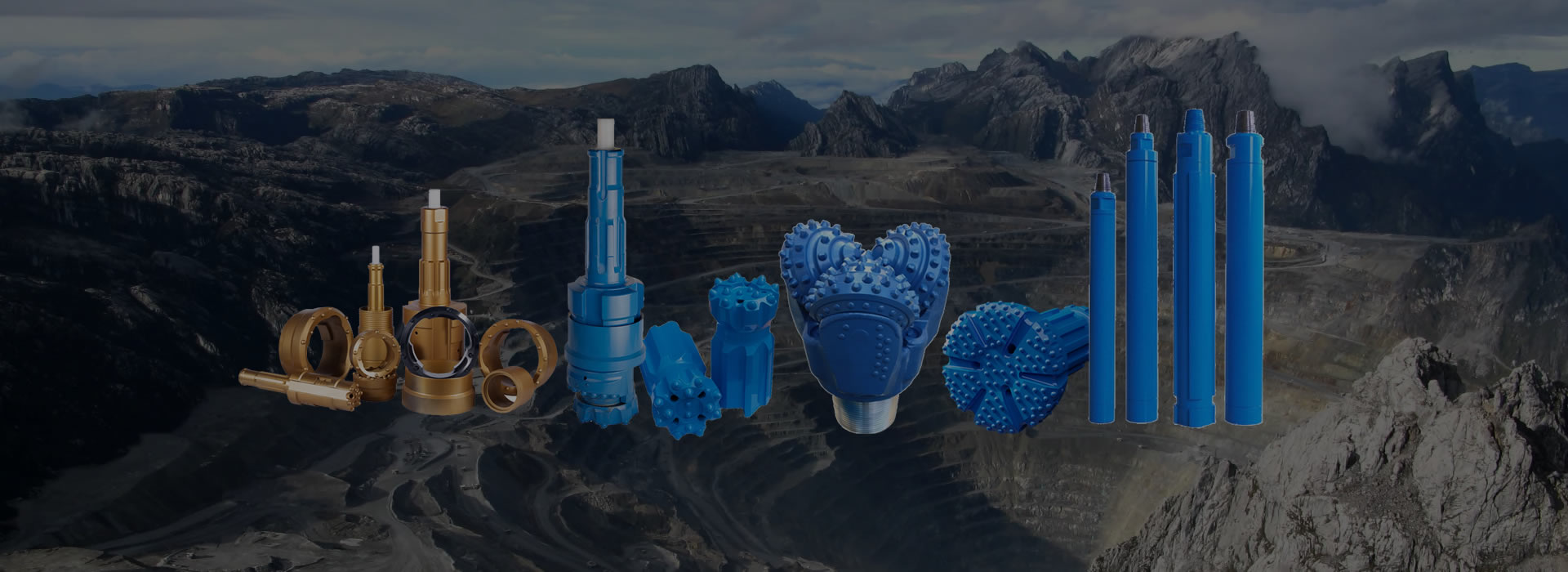

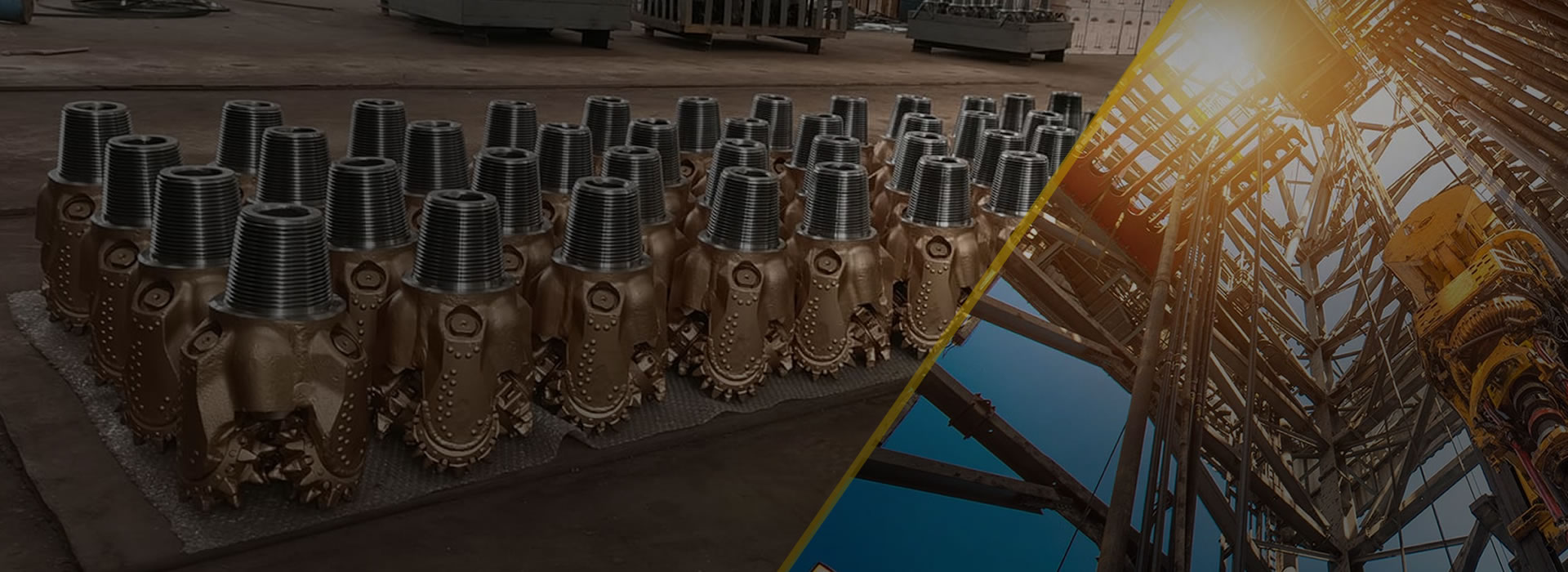

Urang Nawiskeun Alat Pangeboran Awét

Service profésional

Service profésional

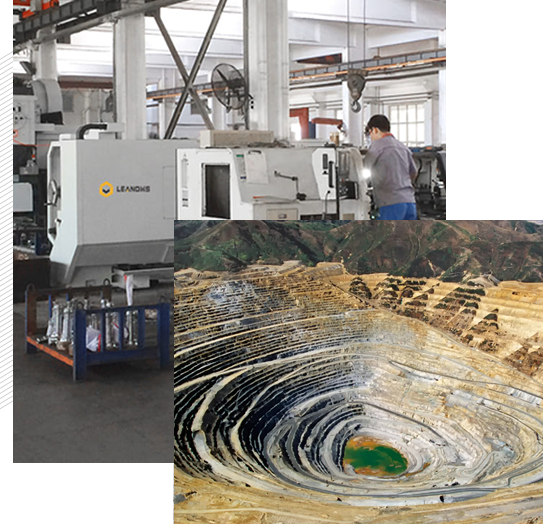

DrillMore Rock Tools Company parantos nyayogikeun industri pangeboran langkung ti 30 taun. Kami khusus dina desain, pamekaran, pabrik, sareng jasa tina bit tricone, alat DTH, Alat Palu Top, Bit PDC pikeun Pertambangan, Pengeboran sumur, Pangeboran Panas Bumi, Konstruksi, Tunneling, Quarrying...

- Supplier profésional

Pikeun Industri PangeboranService Palanggan luar biasa - Desain kualitas luhur

Kontrol Kualitas anu ketatKonsentrasi dina Kompetitif

Warta panganyarna & Apdet