Jou beste boorkeuse

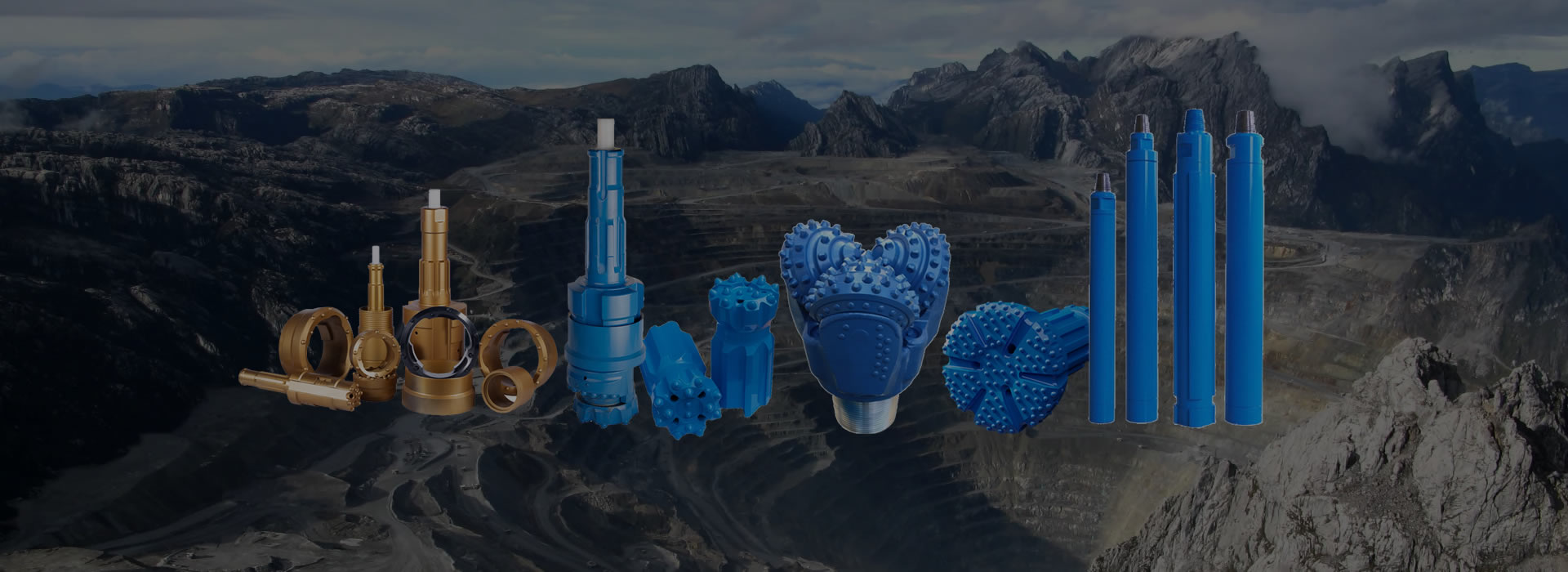

Blaai deur Produkte-kategorieë

3.4k

PROFESSIONELE SPAN

Ingenieur en tegnikus organiseer korrekte materiaal vir skuurprobleem.

25+

R&D

Ons gaan voort om ons stelsel te verbeter, maak seker dat die huidige materiaal stabiel is en stel nuwe saamgestelde voor om nuwe skuurprobleem te pas.

18+

TERREIN DIENS BESKIKBAAR

7x24h tegniese ondersteuning en ons neem 100% verantwoordelikheid vir ons probleem

5.9%

Kliëntediens

Tegniese en kommersiële span volg elke versoek op konsultant of monsters of verskepings op.

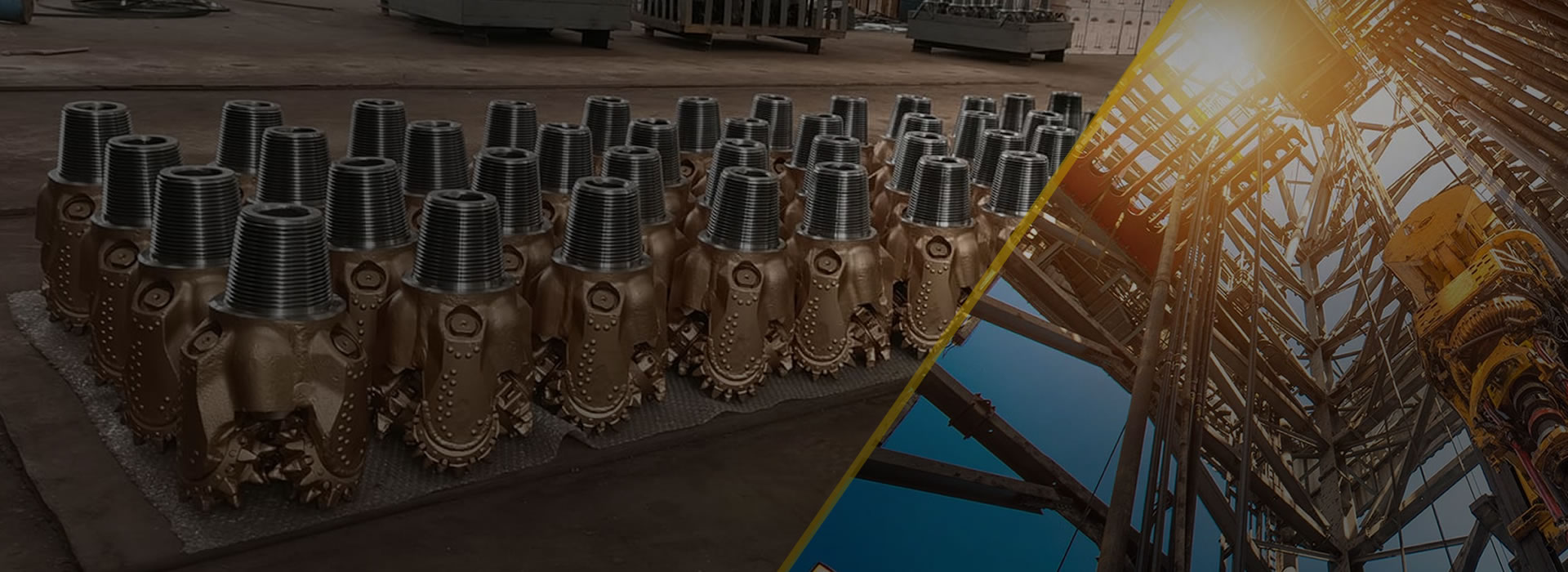

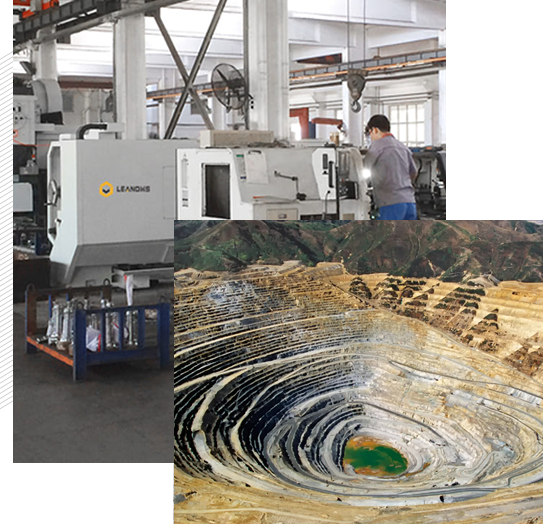

Ons bied duursame boorgereedskap

Professionele diens

Professionele diens

DrillMore Rock Tools Company dien die boorbedryf al meer as 30 jaar. Ons spesialiseer in die ontwerp, ontwikkeling, vervaardiging en diens van tricone-punte, DTH-gereedskap, Top Hammer Tools, PDC Bits vir Mynbou, Boorputte, Geotermiese boor, Konstruksie, Tonneling, Steengroef...

- Professionele verskaffer

Vir industriële boorUitsonderlike kliëntediens - Hoë kwaliteit ontwerp

Streng kwaliteitsbeheerKonsentreer op mededingend

Jongste nuus en opdaterings