Mafi kyawun Zabin Hakowa

Nemo Rukunin Samfura

3.4k

KWAKWALWA MAI SANA'A

Injiniya da mai fasaha suna tsara kayan aiki daidai don matsalar abrasion.

25+

R&D

Muna ci gaba da inganta tsarin mu tabbatar da ingantaccen ingancin kayan yau da kullun kuma muna ba da shawarar sabon haɗe-haɗe don dacewa da sabon matsalar abrasion.

18+

AKAN HIDIMAR SHAFIN

7x24h goyon bayan fasaha kuma muna ɗaukar nauyin 100% akan matsalarmu

5.9%

Sabis na abokin ciniki

Ƙungiyoyin fasaha & kasuwanci suna bin kowane buƙatu akan mai ba da shawara ko samfuri ko jigilar kaya.

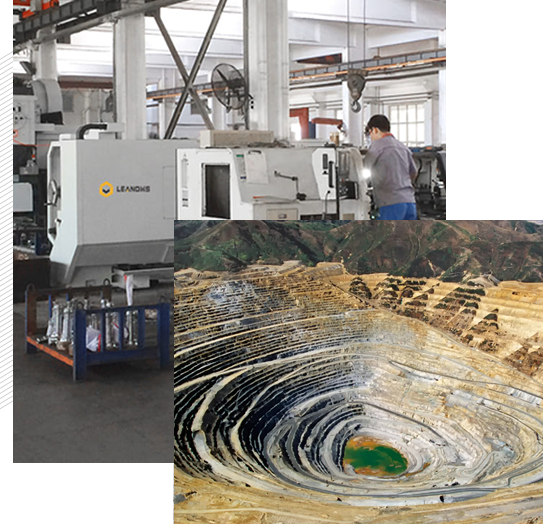

Muna Ba da Kayan Aikin Hakowa Masu Dorewa

Sabis na Ƙwararru

Sabis na Ƙwararru

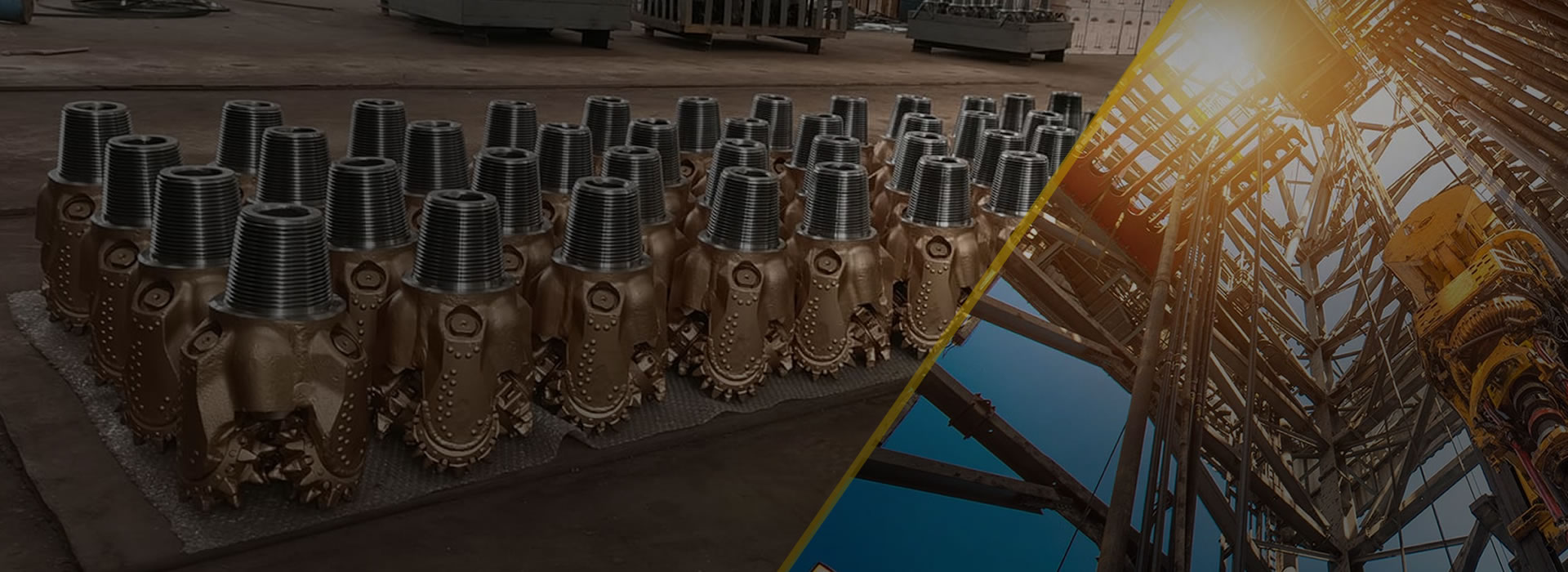

Kamfanin DrillMore Rock Tools Company ya yi hidima ga masana'antar hakar ma'adinai sama da shekaru 30. Mun ƙware a ƙira, haɓakawa, ƙira, da sabis na tricone bits, kayan aikin DTH, Kayan aikin Hammer na Sama, PDC Bits don hakar ma'adinai, haƙon rijiyar, hakowa na Geothermal, Ginawa, Ramin ruwa, Quarrying...

- Ƙwararrun Suroki

Don Hakowa Masana'antuSabis na Abokin Ciniki na Musamman - Zane Mai Kyau

Tsananin Ingancin InganciMai da hankali kan Gasa

Labarai & Sabuntawa