Yako Yakanakisa Drilling Sarudzo

Browse Products Categories

3.4k

CHIKAMU CHEPROFESSIONAL

Injiniya uye tekinoroji vanoronga zvinhu zvakaringana zvedambudziko reabrasion.

25+

R&D

Isu tinoenderera mberi nekuvandudza sisitimu yedu tinoita shuwa kugadzikana mhando yezvinhu zvazvino uye kupa zano nyowani inoumbwa kuti ikwane dambudziko idzva reabrasion.

18+

PASITE SERVICE INOWANIKWA

7x24h technical support uye isu tinotora 100% mutoro padambudziko redu

5.9%

Mabatiro evatengi

Tekinoroji & timu yekutengeserana inoteedzera chikumbiro chega chega pamupi wezano kana masampuli kana kutumira.

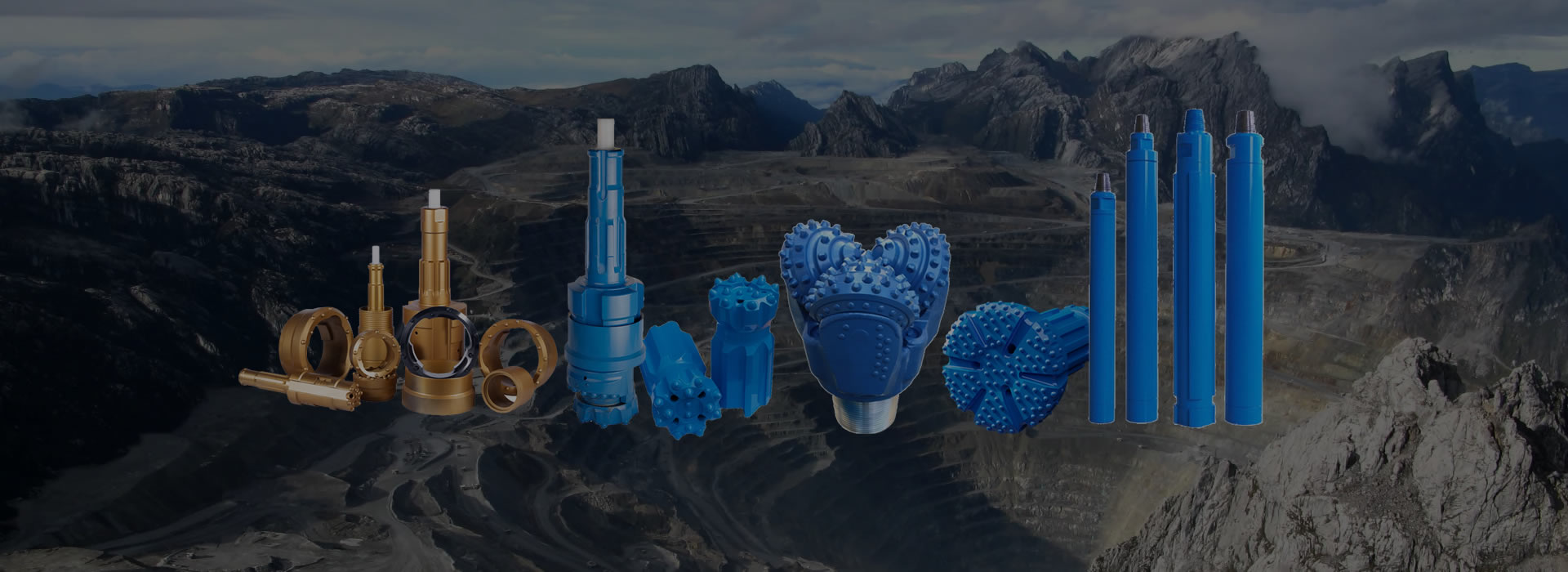

Isu tinopa Durable Drilling Tools

Professional Service

Professional Service

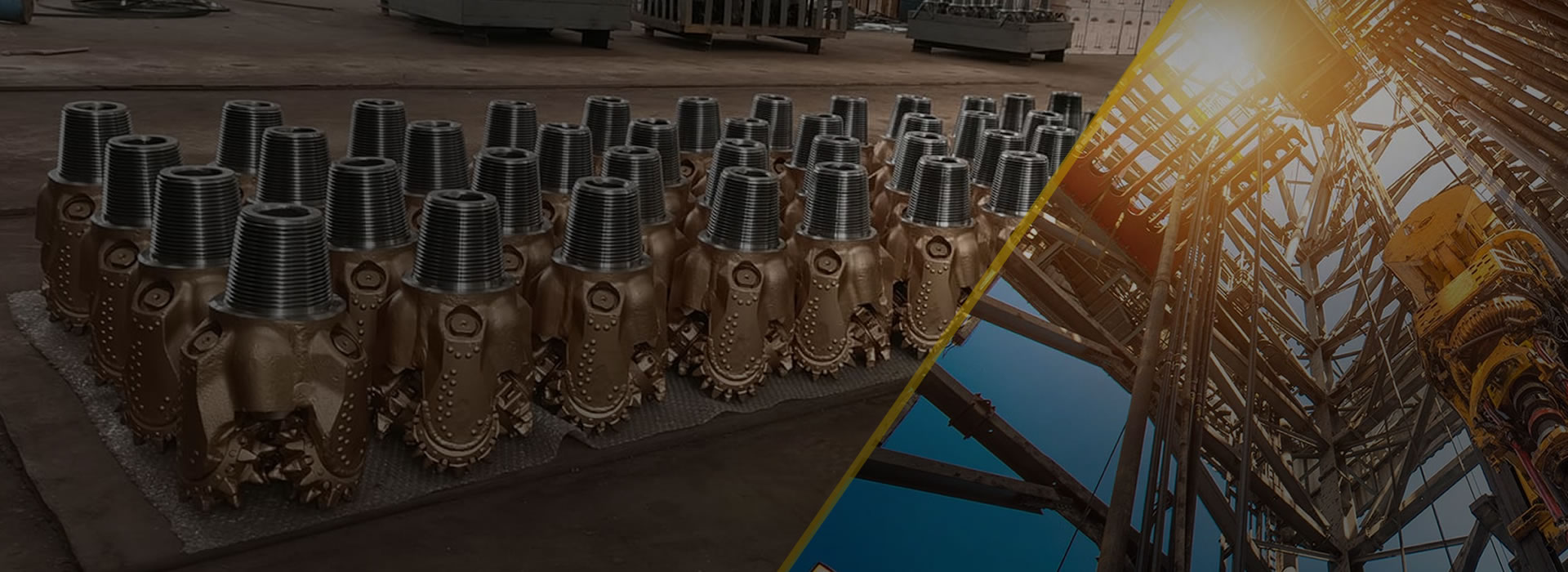

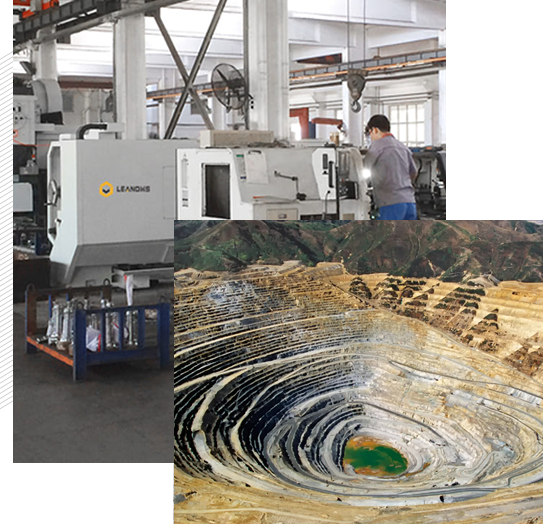

DrillMore Rock Tools Company yakashanda indasitiri yekuchera kweanopfuura makore makumi matatu. Isu tiri nyanzvi mukugadzira, kusimudzira, kugadzira, uye sevhisi ye tricone bits, DTH zvishandiso, Top Hammer Tools, PDC Bits for Mining, Well drilling, Geothermal drilling, Construction, Tunneling, Quarrying...

- Professional Supplier

YeDrilling IndustrialExceptional Customer Service - High Quality Design

Strict Quality ControlIsa pfungwa dzako paKukwikwidza

Latest News & Updates