Vaša najboljša izbira za vrtanje

Prebrskajte po kategorijah izdelkov

3.4k

STROKOVNA EKIPA

Inženir in tehnik organizirata ustrezne materiale za težave z obrabo.

25+

raziskave in razvoj

Še naprej izboljšujemo naš sistem, zagotavljamo stabilno kakovost trenutnih materialov in predlagamo nove kompozite, ki ustrezajo novim težavam z obrabo.

18+

NA VOLJO STORITEV NA KRAJIŠČU

Tehnična podpora 7x24 ur in prevzamemo 100% odgovornost za naš problem

5.9%

Storitev za stranke

Tehnična in komercialna ekipa spremlja vsako zahtevo svetovalca ali vzorcev ali pošiljk.

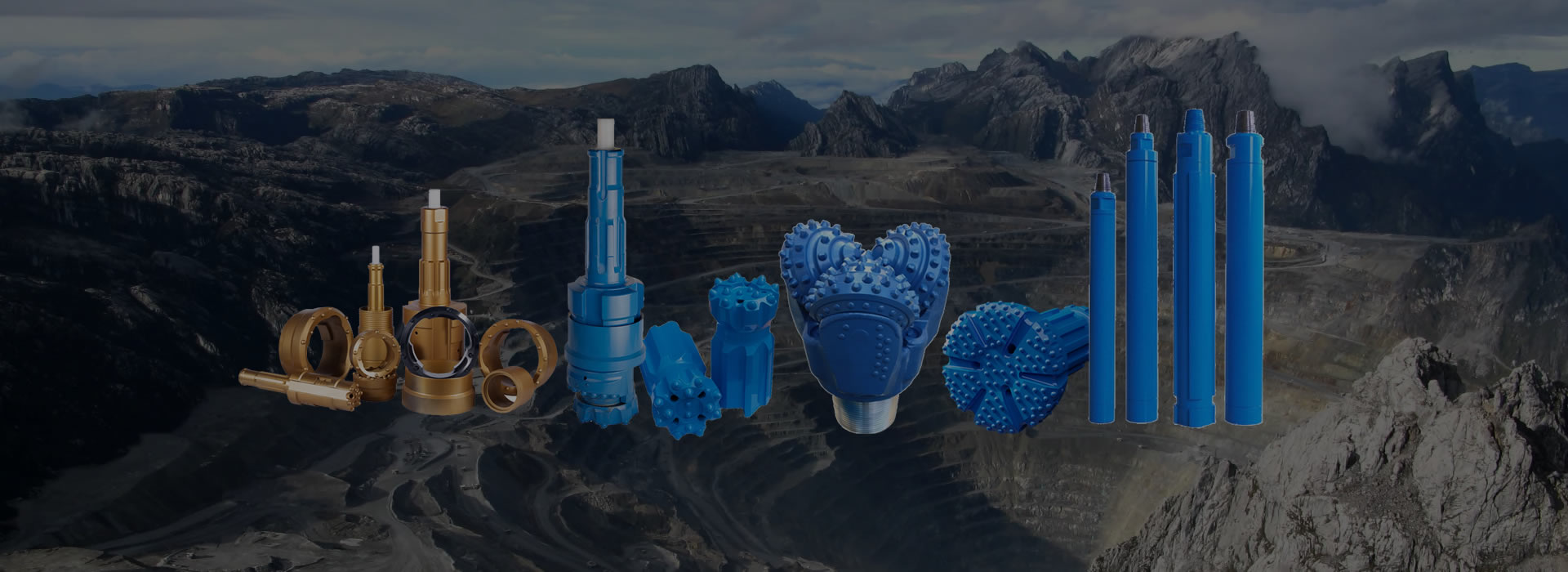

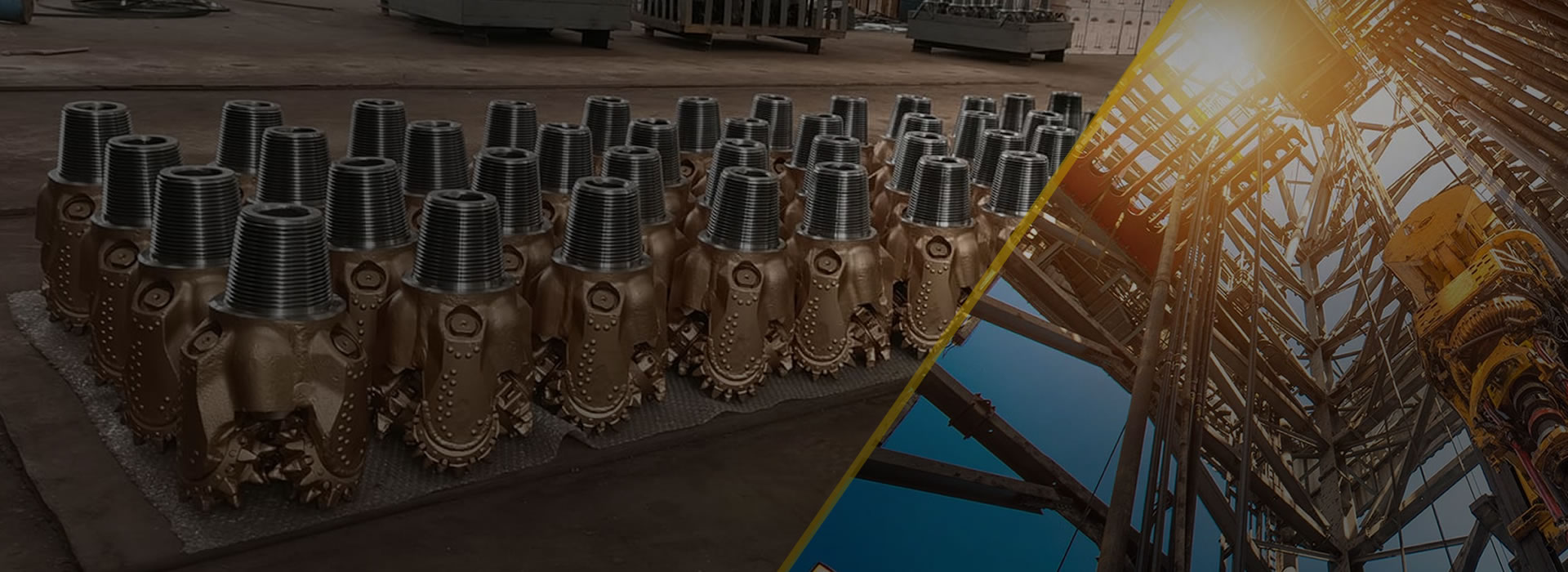

Ponujamo trpežna orodja za vrtanje

Strokovna storitev

Strokovna storitev

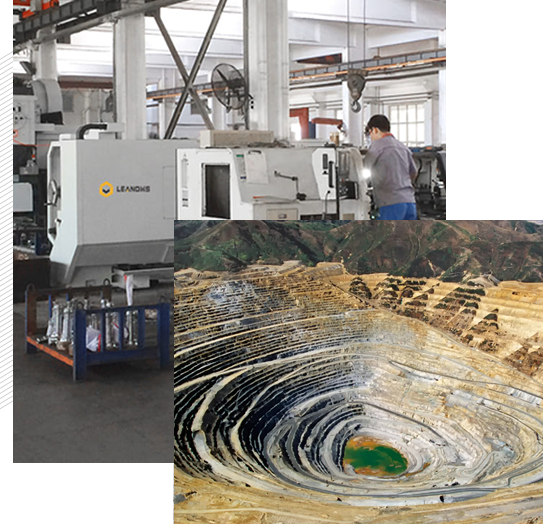

Podjetje DrillMore Rock Tools že več kot 30 let služi industriji vrtanja. Specializirani smo za načrtovanje, razvoj, proizvodnjo in servis trikoničnih nastavkov, DTH orodij, Top Hammer Tools, PDC nastavkov za rudarstvo, vrtanje vodnjakov, geotermalno vrtanje, gradbeništvo, tuneliranje, kamnolome ...

- Profesionalni dobavitelj

Za industrijsko vrtanjeIzjemne storitve za stranke - Visokokakovosten dizajn

Stroga kontrola kakovostiOsredotočite se na konkurenčnost

Zadnje novice in posodobitve