To Kōwhiringa Keri Pai

Tirotiro i nga waahanga hua

3.4k

TE TIMA KAUPAPA

Ko te miihini me te kaitoi te whakarite i nga rawa tika mo te raru abrasion.

25+

R&D

Ka whakapai tonu matou i to maatau punaha kia mau te kounga o nga rawa o naianei me te kii i nga hiato hou kia uru ki nga raru abrasion hou.

18+

I TE RATONGA PAE WAWAIA

7x24h tautoko hangarau me te kawe 100% te kawenga mo o maatau raru

5.9%

Ratonga Kiritaki

Ko te roopu Hangarau me te arumoni ka whai i nga tono katoa mo nga kaitohutohu, tauira, tuku ranei.

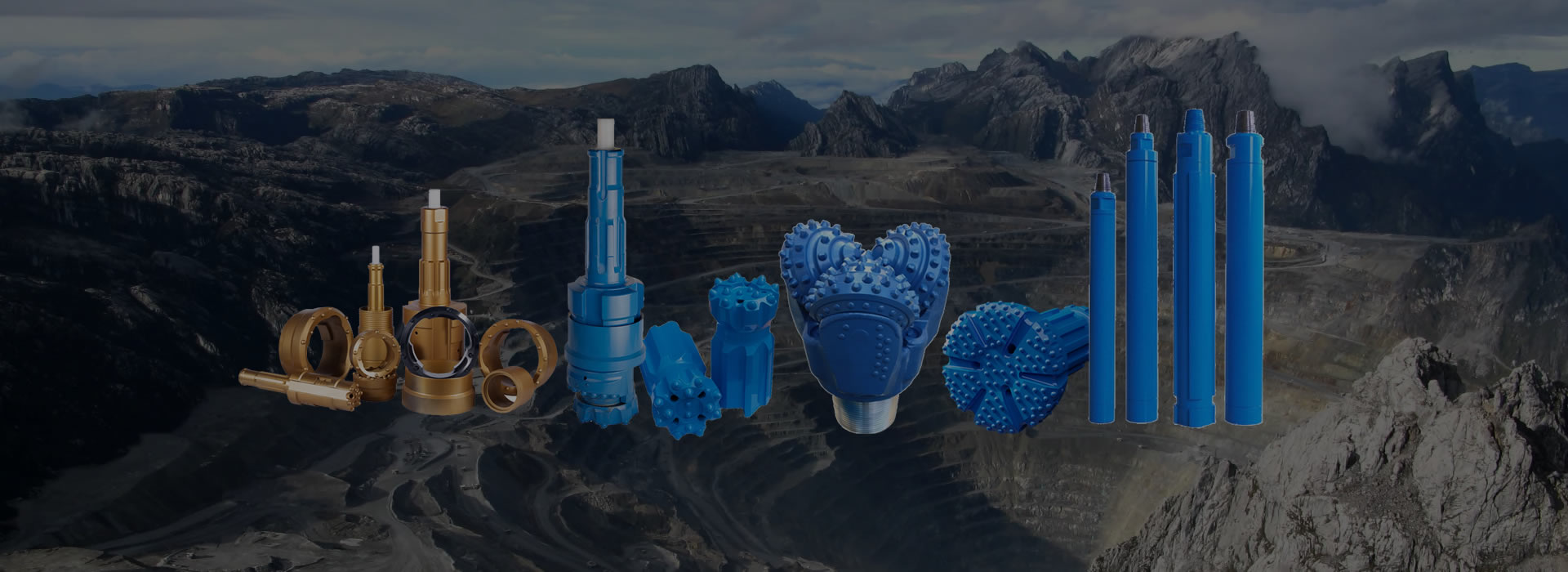

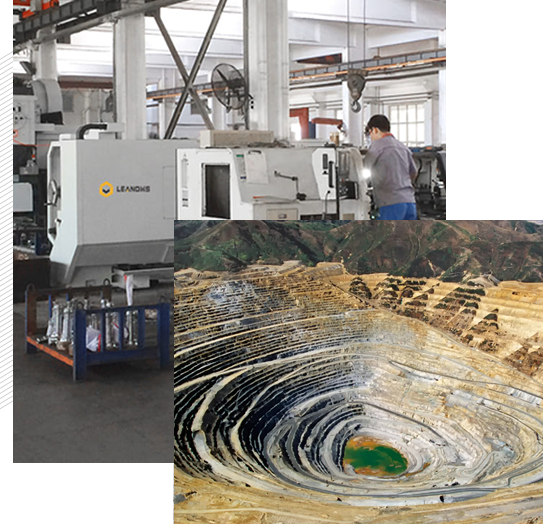

Ka Whakatakotohia e matou nga Utauta Keri Rorohiko

Ratonga Ngaio

Ratonga Ngaio

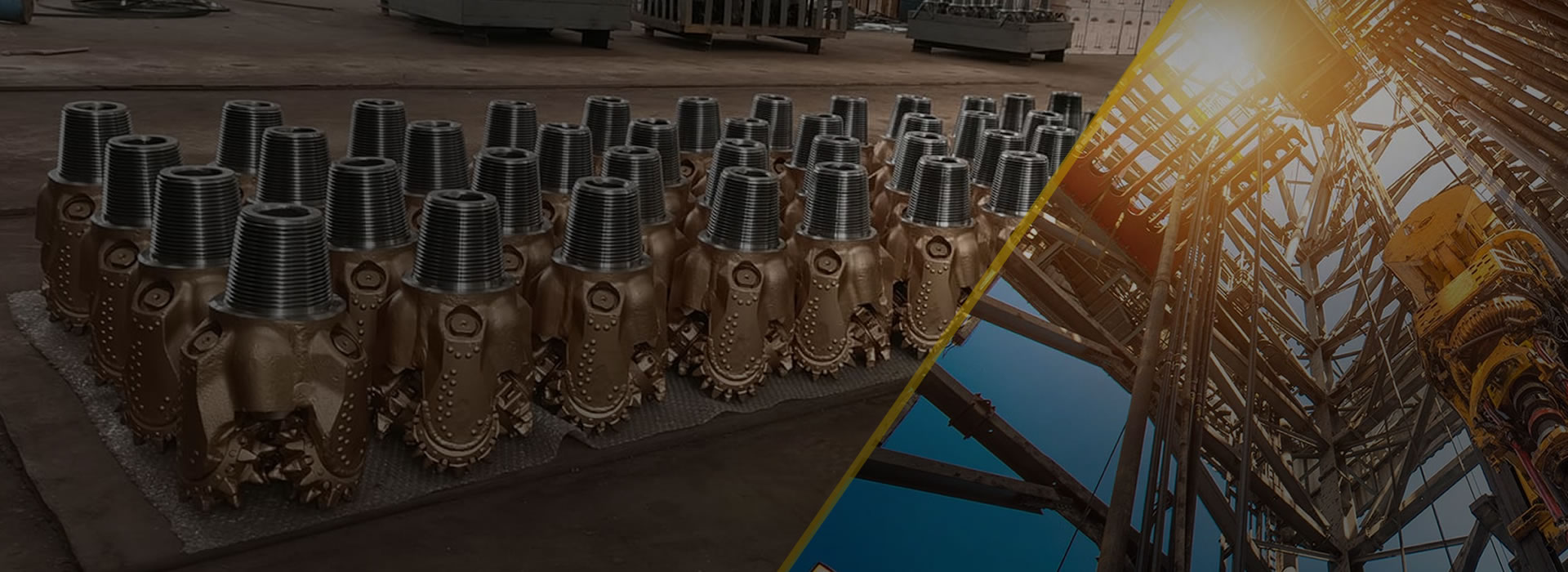

Neke atu i te 30 tau te kamupene DrillMore Rock Tools e mahi ana ki te umanga keri. He tohungatanga matou ki te hoahoa, ki te whakawhanake, ki te hanga, ki te mahi i nga moka tricone, nga taputapu DTH, nga Utauta Hammer Runga, Nga Paraka PDC mo te Maina, Te keri pai, te keri waiariki, te hangahanga, te kohanga, te keri...

- Kaiwhakarato Ngaio

Mo te Ahumahi KeriRatonga Kiritaki Motuhake - Hoahoa Kounga teitei

Mana Kounga TinoTe aro ki te Whakataetae

Nga Korero Hou me nga Whakahoutanga