Är Bescht Buerwahl

Browst Produktkategorien

3.4k

PROFESSIONELL TEAM

Ingenieur an Techniker organiséieren korrekt Material fir Abrasiounsproblem.

25+

R&D

Mir verbesseren weider eise System sécherstellen stabil Qualitéit vun aktuellen Materialien a proposéiere neie Komposit fir nei Abrasiounsproblem ze passen.

18+

ON SITE SERVICE DISPONIBEL

7x24h technesch Ënnerstëtzung a mir huelen 100% Verantwortung op eise Problem

5.9%

Clientszerwiss

Technesch a kommerziell Team verfollegen all Ufro op Beroder oder Proben oder Sendungen.

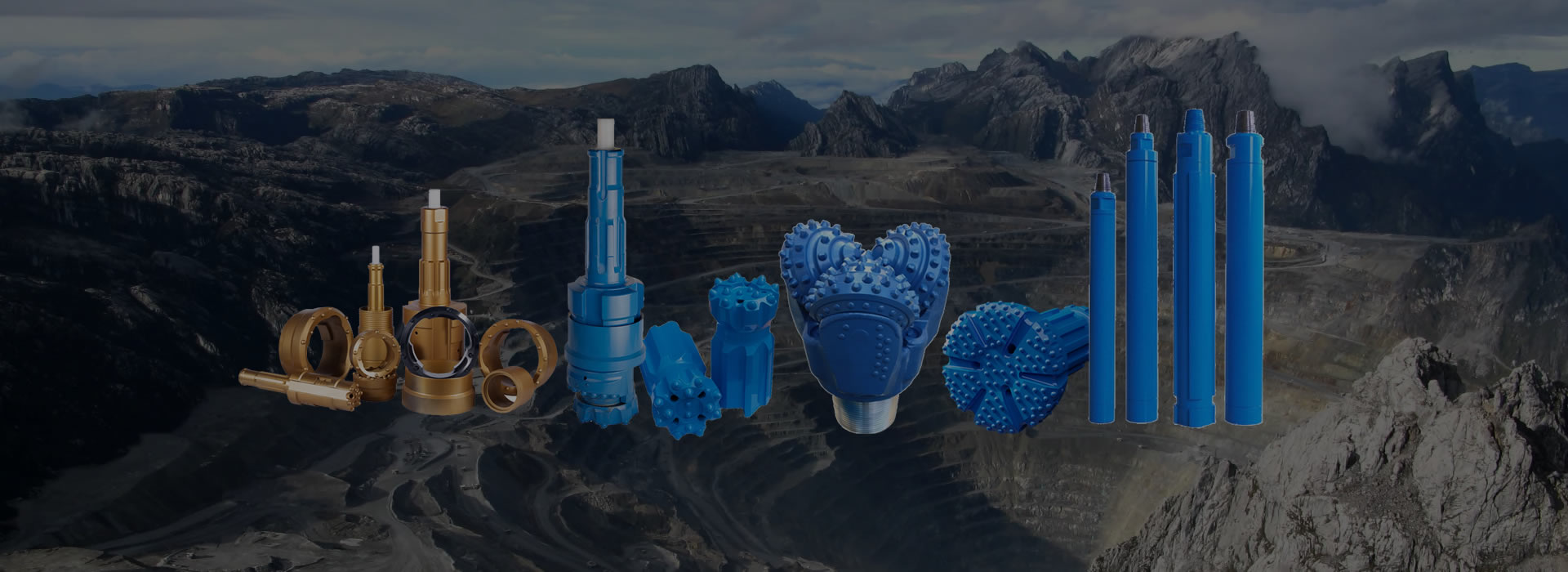

Mir bidden haltbar Drilling Tools

Professionelle Service

Professionelle Service

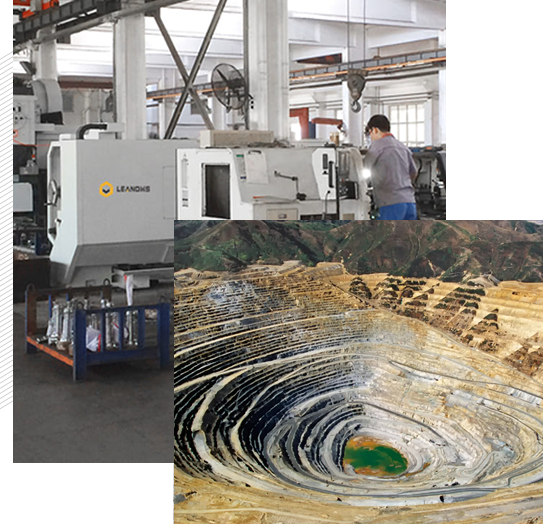

DrillMore Rock Tools Company huet d'Bohrindustrie fir iwwer 30 Joer zerwéiert. Mir spezialiséiert am Design, Entwécklung, Fabrikatioun, a Service vun Tricone Bits, DTH Tools, Top Hammer Tools, PDC Bits fir Biergbau, Well Bueraarbechten, Geothermiebueren, Bau, Tunneling, Quarrying ...

- Berufflech Fournisseur

Fir Bueraarbechten IndustriellAussergewéinlech Client Service - Héich Qualitéit Design

Streng QualitéitskontrollKonzentréieren op kompetitiv

Lescht Neiegkeeten & Updates