Vaš najbolji izbor za bušenje

Pregledajte kategorije proizvoda

3.4k

PROFESIONALNI TIM

Inženjer i tehničar organiziraju ispravne materijale za problem abrazije.

25+

R&D

Nastavljamo da unapređujemo naš sistem osiguravamo stabilan kvalitet postojećih materijala i predlažemo novi kompozit koji će odgovarati novom problemu abrazije.

18+

DOSTUPNA USLUGA NA SITEU

Tehnička podrška 7x24h i preuzimamo 100% odgovornost za naš problem

5.9%

Korisnička podrška

Tehnički i komercijalni tim prati svaki zahtjev za konsultantima ili uzorcima ili pošiljkama.

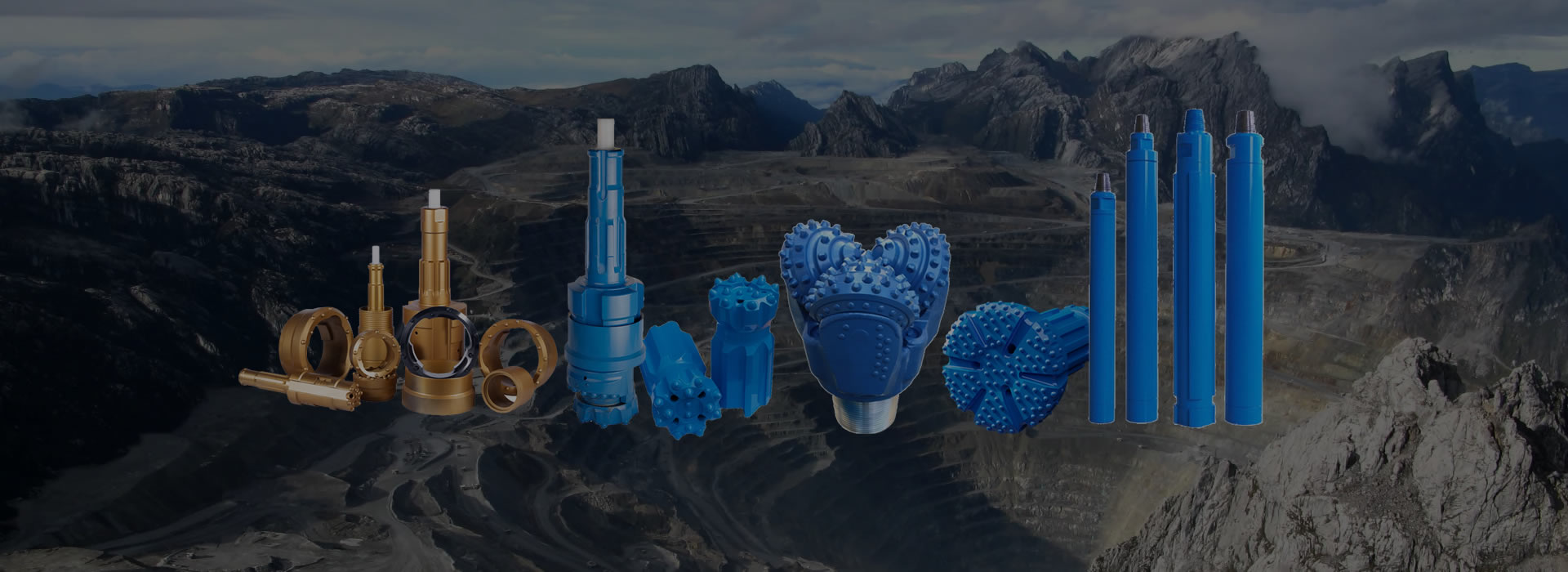

Nudimo izdržljive alate za bušenje

Profesionalna usluga

Profesionalna usluga

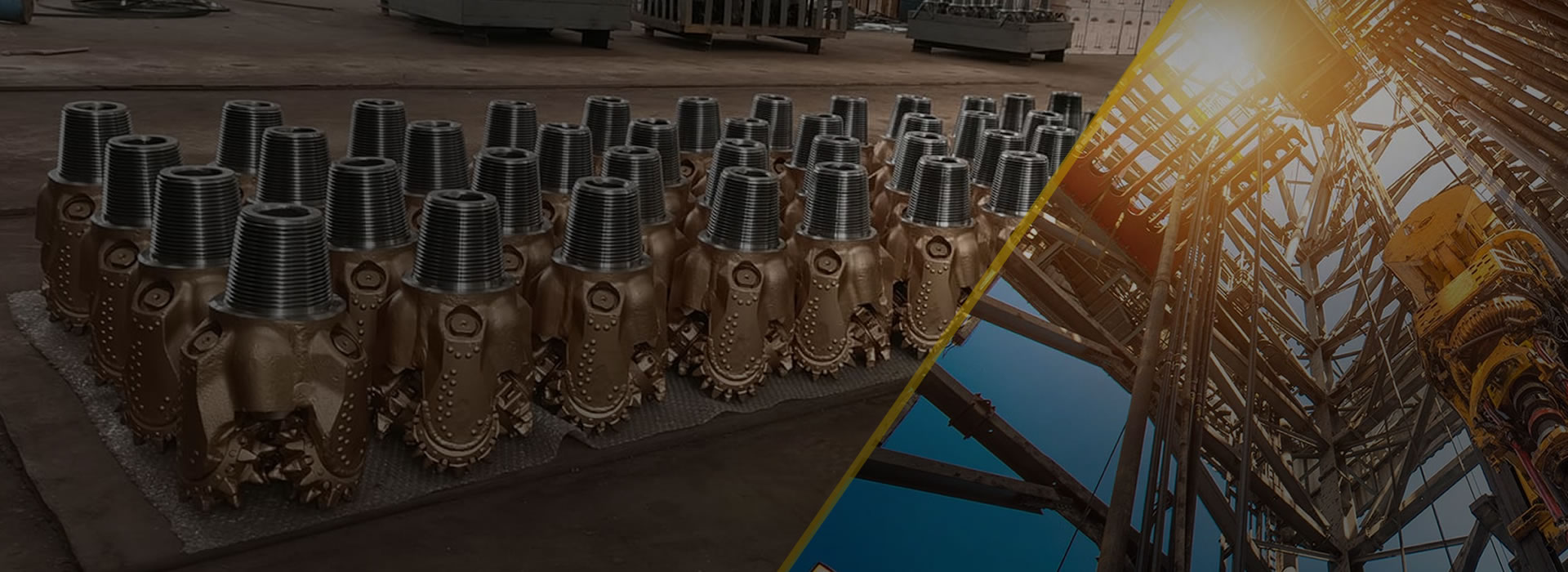

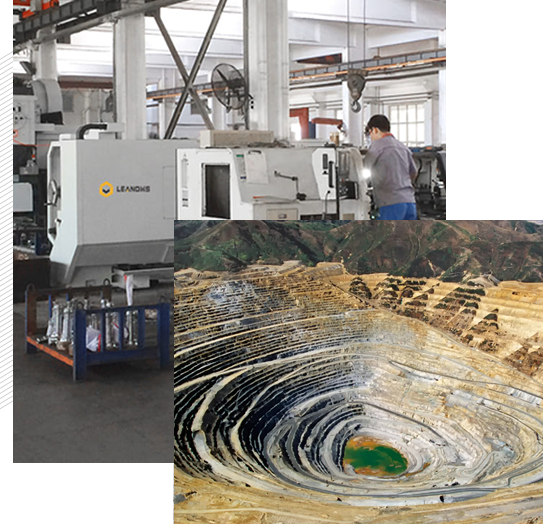

DrillMore Rock Tools Company služi industriji bušenja više od 30 godina. Specijalizirani smo za dizajn, razvoj, proizvodnju i servis trokonusnih bitova, DTH alata, Top Hammer alata, PDC bitova za rudarstvo, bušenje bunara, geotermalno bušenje, građevinarstvo, tuneliranje, vađenje...

- Profesionalni dobavljač

Za industrijsko bušenjeIzuzetna korisnička usluga - Visok kvalitet dizajna

Stroga kontrola kvalitetaKoncentrišite se na konkurentnost

Najnovije vijesti i ažuriranja