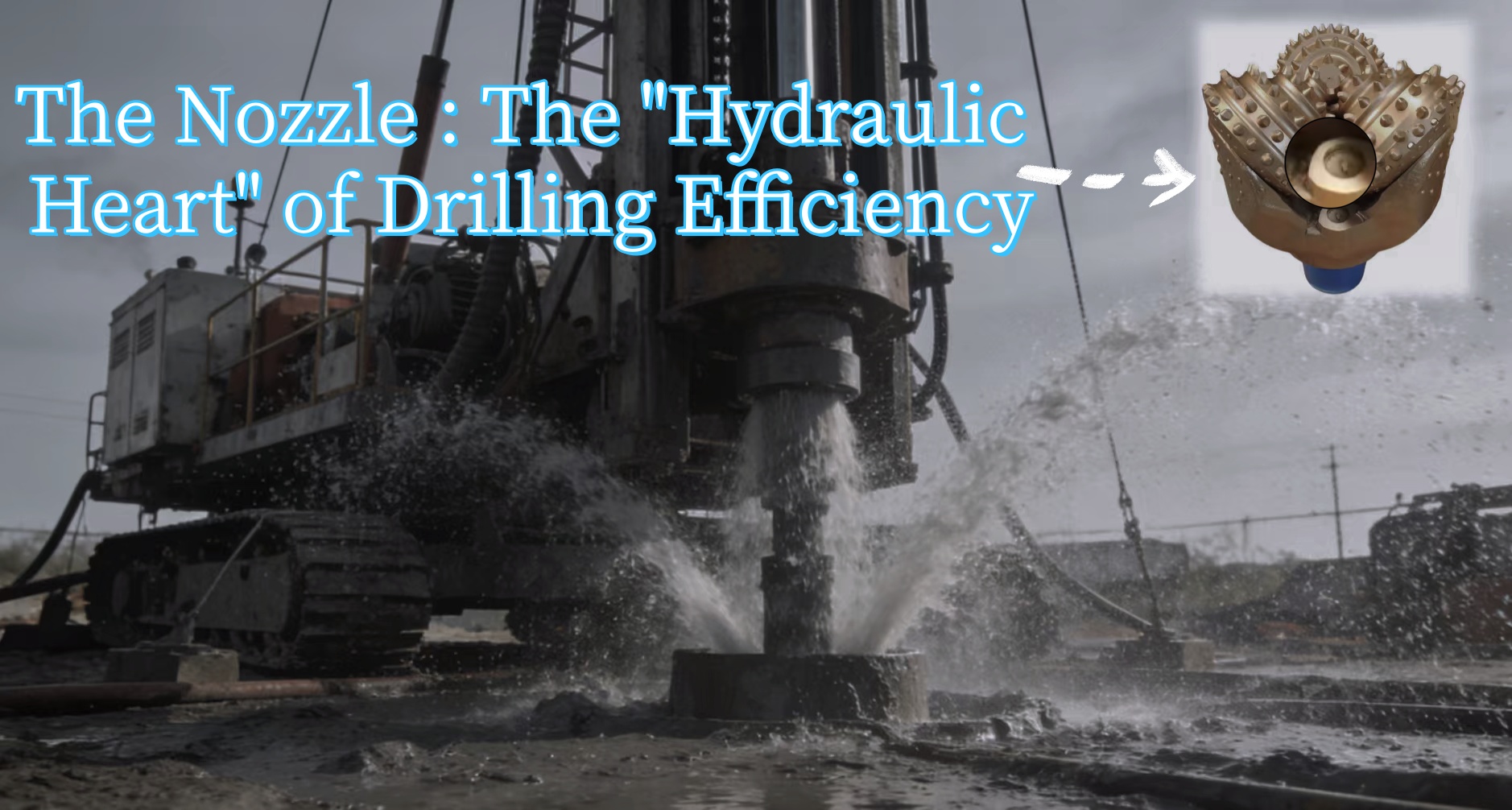

The Nozzle of the Tricone Drill Bit: The "Hydraulic Heart" of Drilling Efficiency

Among the complex components of a tricone drill bit, the nozzle is often seen as a small, easily overlooked part. Yet it is truly the hydraulic heart that determines drilling efficiency, bit life, and downhole safety. More than just a passage for drilling fluid (mud) to exit the bit, nozzles are central to efficient rock breaking, botton hole cleaning, and stable operation. In this article, we break down the core functions of tricone drill bit nozzles and show why such a small part makes such a big difference.

1. Cooling and Lubrication: Protecting the Bit’s "Lifeline"

When a cone bit rotates and breaks rock at high speed, intense friction between bearings, cone teeth, and the formation generates large amounts of heat. Without proper heat dissipation, bearings can overheat and fail, teeth wear accelerates, and bit service life drops sharply.

Cooling: High velocity drilling fluid jets from the nozzles directly cool the cones and bearings, quickly removing frictional heat and keeping the bit within a safe temperature range.

Lubrication: Drilling fluid forms a lubricating film on bearings and cone surfaces, reducing direct metal to metal friction, lowering wear, and extending the operating life of the bit. The cooling and lubrication effect of nozzles is especially critical in high temperature deep wells and hard formation drilling, directly determining whether a bit can reach its planned drilling distance.

2.Cleaning the Bottom Hole and Tooth Surfaces:

Key to Preventing Bit BallingCuttings left at the bottom hole or trapped between cone teeth cause bit balling — a problem that increases drilling resistance, reduces breaking efficiency, and can even lead to pipe sticking. Nozzles solve this problem at the source.

Removing cuttings: High velocity jets flush the bottom hole and cone teeth, promptly clearing broken cuttings to avoid repeated crushing. This ensures teeth continuously contact fresh rock.

Preventing balling:Sustained fluid flow stops cuttings from sticking to cones and the bit body, keeping the bit clean and drilling smooth. In soft or sticky formations, the cleaning performance of nozzles directly affects drilling efficiency and downhole safety.

3. Assisting Rock Breaking: The "Booster" for Improving Rate of Penetration

Nozzle jets do more than clean the bottom hole — they actively participate in rock breaking and greatly improve the rate of penetration (ROP).

Rock breaking in soft formations: In soft formations, high velocity jets can directly shock and weaken rock, creating a pre broken zone. This reduces the mechanical load on the cones and significantly increases ROP.

Efficiency improvement in hard formations: In hard formations, jets may not break rock directly, but they improve bottom hole cleanliness, allowing cone teeth to engage rock more effectively and reduce ineffective wear, indirectly enhancing breaking efficiency. Well designed nozzle jets help the bit perform optimally across different formation types.

4. Optimizing Bottom Hole Flow Field: Enhancing Cutting Carrying

The number, position, diameter, and spray angle of nozzles together define the bottom hole flow field. A good nozzle design eliminates "dead zones" where fluid stagnates, distributes drilling fluid more evenly across the bottom, and ensures efficient cuttings transport to the surface.

Eliminating dead zones: Properly arranged nozzles prevent fluid stagnation and cuttings accumulation at the bottom hole.

Protecting the wellbore: Optimized jet angles reduce erosion of the wellbore wall, improve stability, and lower the risk of collapse. In complex well types such as extended reach and horizontal wells, bottom hole flow field optimization directly affects cutting carrying and wellbore quality.

5. Adjusting Hydraulic Parameters: Adapting to Different Operating Conditions

Nozzle diameter directly affects pressure drop across the bit. By selecting nozzles of different sizes, engineers can accurately regulate bottom hole pressure and flow rate to match the requirements of various formations and well types.

Adapting to formations:In high pressure formations, larger nozzles reduce pressure drop to prevent lost circulation. In low pressure formations, smaller nozzles increase pressure drop and improve cutting carrying.

Ensuring tool stability: In directional wells, proper nozzle design helps maintain stable performance of measurement while drilling (MWD) and logging while drilling (LWD) tools while preserving efficient cuttings transport. Nozzle selection is, in essence, precise control of drilling hydraulic parameters.

The nozzle of a tricone drill bit, though small in size, performs multiple vital functions: cooling and lubrication, bottom hole and tooth cleaning, assisted rock breaking, flow field optimization, and hydraulic regulation. It serves as the bridge between drilling fluid and the drill bit, and is essential for efficient, safe drilling.

For high-performance nozzles for tricone drill bits, choose DrillMore.Our nozzles deliver excellent cooling, cleaning and hydraulic efficiency to improve your drilling speed.DrillMore helps you extend bit life and lower operating costs with reliable, field-proven quality.

Your email address will not be published. Required fields are marked with *