Do You Know What The Construction Process of a Horizontal Directional Drill is Like?

I. Site Preparation

After the site is leveled and the mud pit and sedimentation tank are constructed, prepare for the directional drilling of the drilling rig.

II. Positioning of Directional Drilling Rig

III. Guided Drilling

The drilling rig drills in sandy or clay layers. During drilling, it should advance at a uniform speed, and strictly control the drilling feed force and direction. The entry section and exit section should be straight drilling, with the straight length preferably controlled at about 20 meters.

DrillMore's horizontal directional drilling rigs feature:

1. Precise guiding capability: Equipped with high-precision guiding systems (such as geomagnetic positioning, gyroscopes) to ensure the borehole trajectory highly matches the design and reduce deviations.

2. Drill bit adaptability: The drill bit is made of wear-resistant material with sharp edges, capable of handling different geologies (such as clay, sand, soft rock) and featuring strong flexible steering performance.

3. Power stability: The rig provides smooth thrust and torque output to avoid trajectory deviation caused by power fluctuations during drilling.

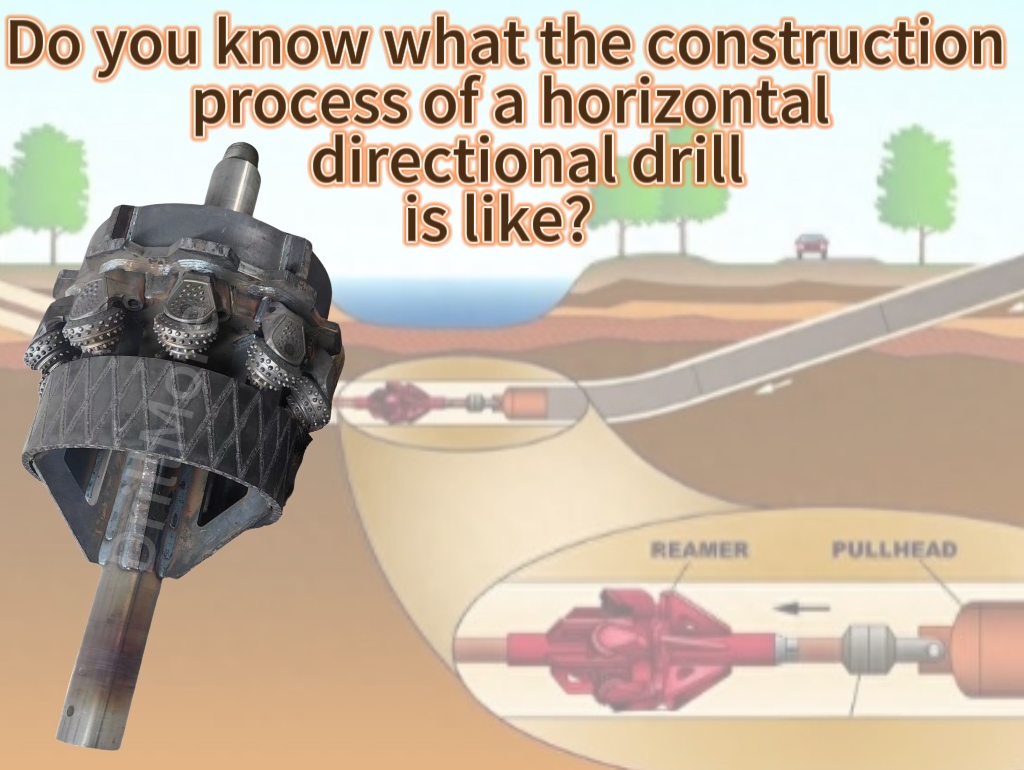

IV. Reaming

After the drill bit exits the target position, replace it with a larger drill bit. During the reaming and back-reaming process, pull the pipeline in to complete the laying. Reaming should be completed in one or multiple times according to conditions such as the medium hole diameter, pipeline area radius, soil layer conditions, and equipment capacity. The most critical point of this technology is the initial directional control of the drill bit underground. Since it is necessary to move from point A to point B along the scheduled route, the drill pipe must advance smoothly underground while avoiding other underground facilities, such as manholes and other pipelines. Therefore, a sensor is installed inside the drill bit, which real-time transmits information such as the drill bit's angle, depth, temperature, etc. For example, to make the drill bit move upward, maintain an upward angle without rotating, and push the drill pipe forward directly, so the drill bit will tilt upward. The same principle applies to left or right deviations. Finally, engineers will guide the drill bit to exit from the pre-dug pit based on its depth and angle.

DrillMore's horizontal directional drilling rigs feature:

1. High-strength reamer: The reamer is made of high-strength alloy, resistant to impact and wear, capable of efficiently crushing rocks or hard soil to ensure uniform hole expansion.

2. High slag discharge efficiency: Equipped with a strong mud circulation system to timely discharge drill cuttings, avoiding sedimentation in the hole from affecting reaming quality and subsequent backhaul.

3. Strong coordination between drilling and reaming: The rig's power system can match the reamer size to ensure stable torque and tension during reaming, reducing the risk of hole wall collapse.

V. Pipeline Backhaul

After reaming is completed, carry out pipeline backhaul construction. At this time, the swivel and reaming drill bit... Before backhaul, clean the hole to remove the mud residue in the hole after reaming. Backhaul should proceed continuously from the exit point to the entry point, using a uniform and slow pulling method. Hard pulling is strictly prohibited. After the pipeline backhaul is completed, clean the construction site to finish the project.

DrillMore's horizontal directional drilling rigs feature

1.pipeline backhaul resistance, and the traction force output is linearly controllable to avoid pipeline damage caused by excessive instantaneous tension.

2. Pipeline protection design: The mud lubrication system is efficient during backhaul to reduce friction between the pipeline and the hole wall, while equipped with a tension monitoring device to adjust the backhaul speed in real-time.

3. Equipment reliability: The hydraulic system and transmission components have good sealing performance to avoid mid-backhaul failures and ensure one-time backhaul success.

This pipeline laying technology plays a vital role in modern urban construction due to its minimal damage and small footprint, and it has now been widely popularized.

Your email address will not be published. Required fields are marked with *