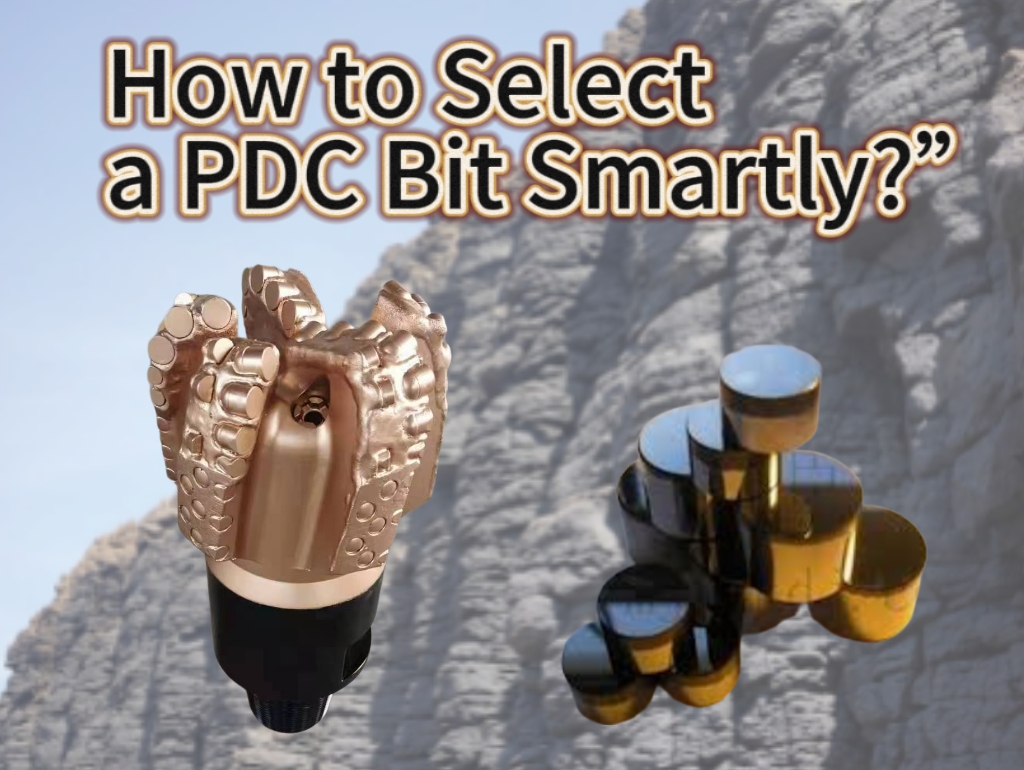

How to Select a PDC Bit Smartly?

1. Rock Hardness: A Contest of Hardness and Flexibility

Core indicator: The ability of rock to resist plastic deformation or scratching.

Challenges in hard rocks (such as granite, basalt): High hardness easily leads to chipping of cutting teeth and severe wear of the drill bit. Characteristics of suitable drill bits:

High-strength cutting teeth: High-quality PDC Cutter with strong impact resistance and good thermal stability should be selected.

Thick blade design: Enhance the structural strength of the blade body to resist the reaction force of the rock.

Small cutting angle: More negative rake angles (such as -15° to -25°) are usually adopted, mainly for "scraping" to reduce the risk of brittle fracture and improve penetration.

Reinforced gauge protection design: Prevent the drill bit diameter from decreasing rapidly due to severe wear.

2. Rock Abrasiveness: The Ultimate Test of Durability

Core indicator: The ability of rock to wear cutting teeth and the drill bit body (closely related to the content of hard minerals such as quartz).

Highly abrasive rock formations (such as quartz sandstone, coarse-grained granite, chert layers):

Characteristics of suitable drill bits:

Ultra-wear-resistant cutting teeth: Use PDC layers with higher thermal stability and stronger wear resistance.

Dense tooth arrangement strategy: Increase the number of cutting teeth to share the wear load of a single tooth.

Optimized hydraulic structure: Ensure efficient removal of cuttings to avoid accelerated wear due to secondary grinding.

Reinforced gauge protection/abrasion-resistant areas: Hardfacing carbide or inlaying diamond materials in the shoulder and gauge protection areas.

3. Formation Structure and Homogeneity: Adaptability to Complex Formations

Core considerations: The degree of development of bedding, joints, fractures in the rock formation, and the situation of alternating hard and soft layers.

Complex formations (such as fault fracture zones, shale with strongly developed joints, sandstone-mudstone interbeds):

Characteristics of suitable drill bits:

High impact resistance: Cutting teeth and drill bit body must be able to withstand the impact load caused by sudden changes in the formation.

Stability design: Good force balance design (low torque fluctuation) and gauge protection structure to prevent excessive vibration or deflection of the drill bit in fracture zones or soft layers.

Flexible cutting structure: May adopt mixed tooth sizes or different back rake angle designs to enhance adaptability in heterogeneous rock formations.

4. Drilling Parameters: The Stage for Performance

Core matching: The design of the drill bit needs to match the expected range of weight on bit (WOB) and rotation speed (RPM).

Key points:

High WOB/low RPM: Usually suitable for hard formations, requiring the drill bit to have a stronger structure (such as thick blades) and negative angle cutting teeth.

Low WOB/high RPM: Suitable for soft to medium-hard formations, the drill bit can be designed with sharper positive angle cutting teeth and a hydraulic structure conducive to chip removal.

Parameter optimization: Even if the drill bit itself is suitable for the rock formation, unreasonable drilling parameters (such as excessive WOB impacting hard formations, insufficient displacement leading to cuttings accumulation) will cause premature damage to the drill bit or low efficiency.

5. Types of PDC Drill Bit: Each Has Its Specialty

Core classification: According to design goals and application scenarios, there are main types of PDC Drill Bit:

Standard type: Versatile, suitable for medium-soft to medium-hard, homogeneous formations.

Enhanced/impact-resistant type: Reinforced structure (such as thickened blades, enhanced gauge protection, impact-resistant teeth), specially designed for hard formations, fracture zones or high-vibration environments.

Highly abrasive-resistant type: Using the most wear-resistant materials, dense tooth arrangement and reinforced gauge protection, specializing in highly abrasive formations (such as quartz sandstone).

Deep/ultra-deep well type: Special emphasis on thermal stability and reliability in high-temperature and high-pressure environments.

Directional/horizontal well special type: Optimized for guidance, stability and anti-whirl ability.

Conclusion: Multi-dimensional decision-making for precise matching

Your email address will not be published. Required fields are marked with *