Your Best Drilling Choice

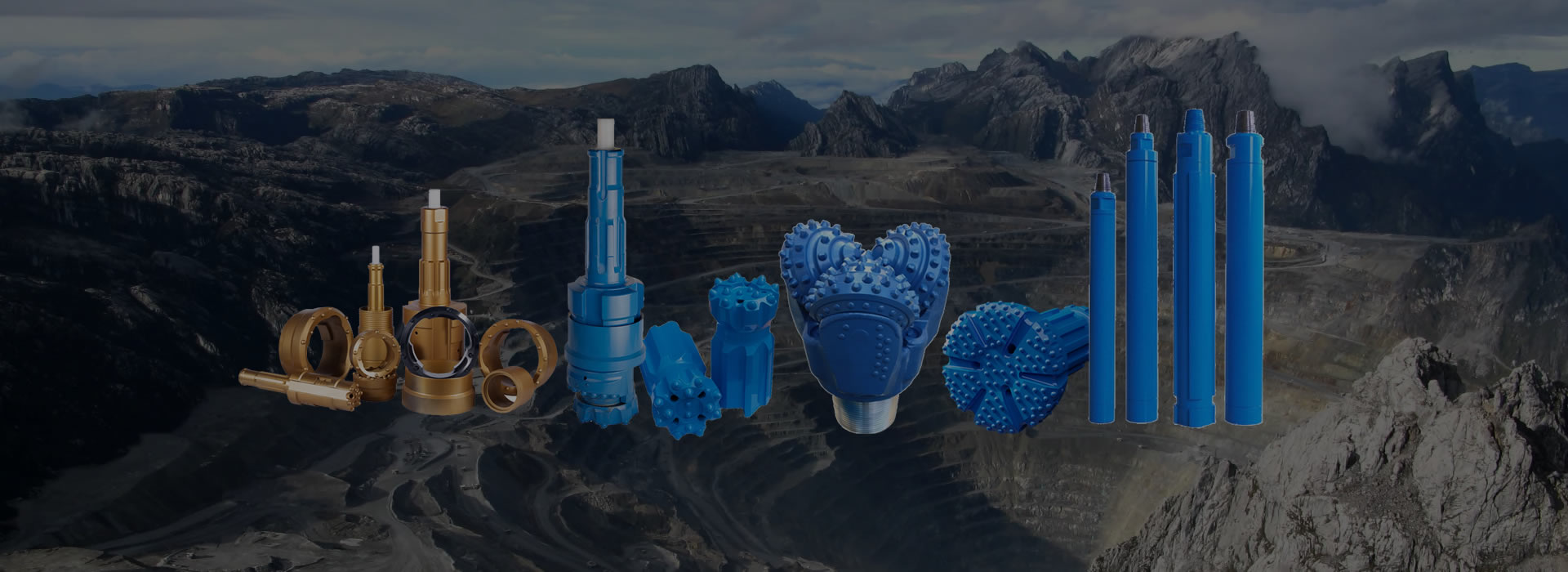

Browse Products Categories

3.4k

PROFESSIONAL TEAM

Engineer and technician organize correct materials for abrasion problem.

25+

R&D

We continue improve our system make sure stable quality of current materials and suggest new composite to fit new abrasion problem.

18+

ON SITE SERVICE AVAILABLE

7x24h technical support and we take 100% responsibility on our problem

5.9%

Customer service

Technical & commercial team follow up every request on consultant or samples or shipments.

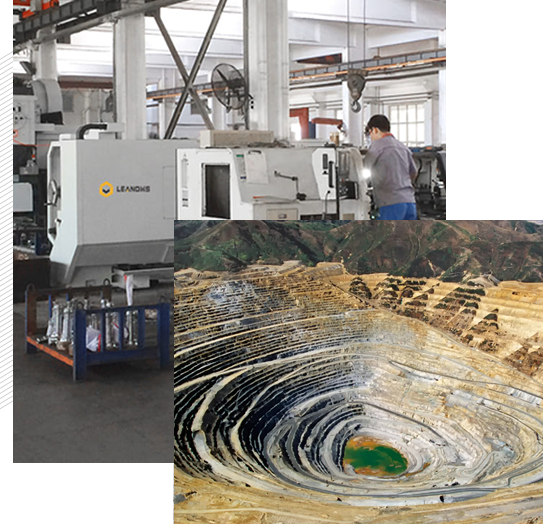

We Offer Durable Drilling Tools

Professional Service

Professional Service

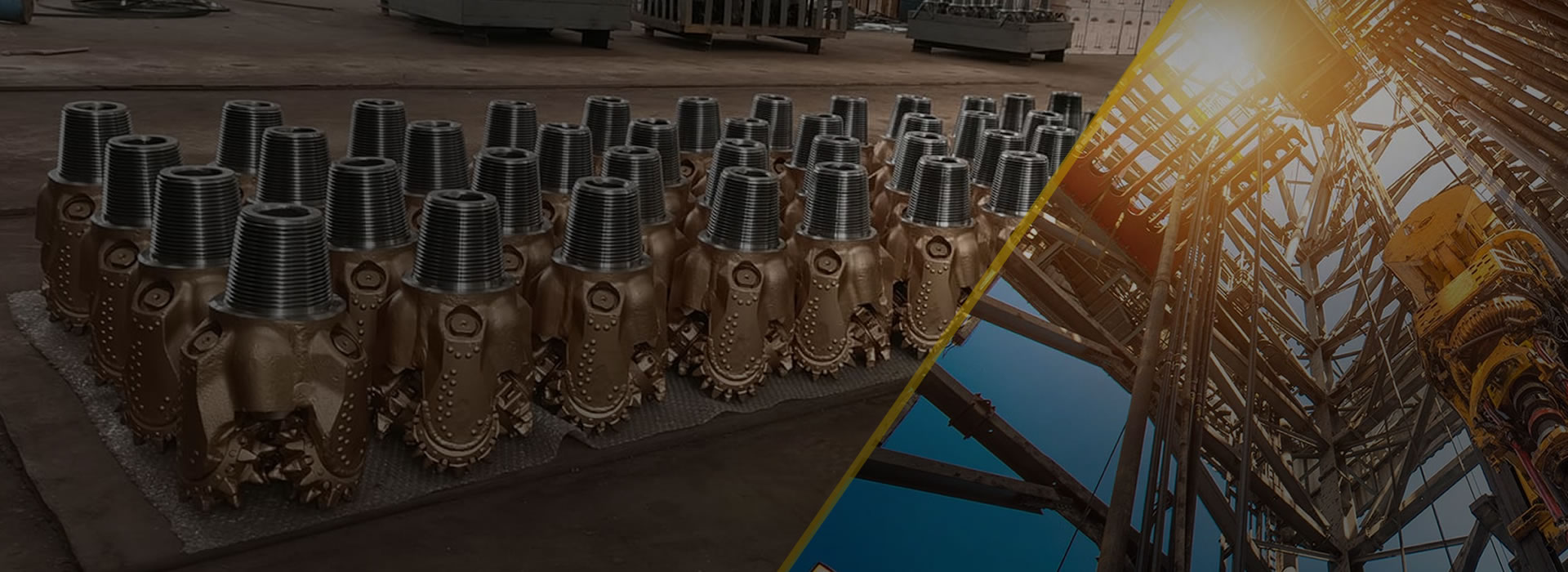

DrillMore Rock Tools Company has served the drilling industry for over 30 years. We specialising in the design, development, manufacture, and service of tricone bits, DTH tools, Top Hammer Tools, PDC Bits for Mining, Well drilling, Geothermal drilling, Construction, Tunneling, Quarrying...

- Professional Supplier

For Drilling IndustrialExceptional Customer Service - High Quality Design

Strict Quality ControlConcentrate on Competitive

Latest News & Updates