Differences Between Tricone Bits for Mining and Water Wells

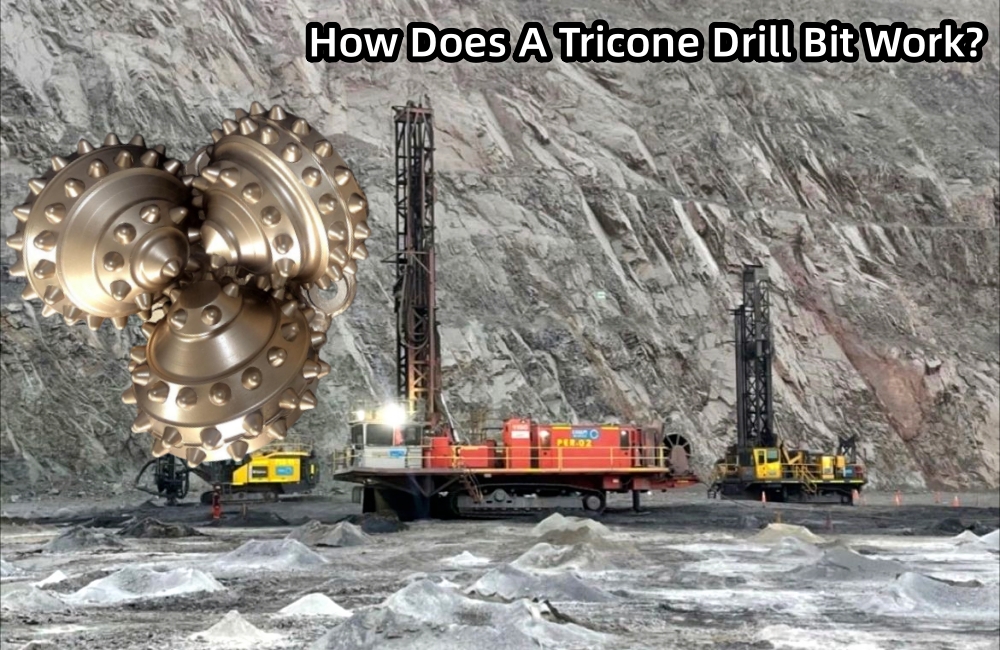

In the engineering field of exploring the mysteries of the earth's crust, tricone bits have become indispensable tools due to their excellent rock-breaking capabilities. However, when facing vastly different working environments—the hard and dry mining rock formations versus the soft and water-bearing underground aquifers—tricone bits have evolved into two distinct branches: mining bits with compressed air as their "bloodline" and water well bits with mud as their "lifeblood". The subtle differences in their structures are a perfect interpretation of engineering adaptability.

In the engineering field of exploring the mysteries of the earth's crust, tricone bits have become indispensable tools due to their excellent rock-breaking capabilities. However, when facing vastly different working environments—the hard and dry mining rock formations versus the soft and water-bearing underground aquifers—tricone bits have evolved into two distinct branches: mining bits with compressed air as their "bloodline" and water well bits with mud as their "lifeblood". The subtle differences in their structures are a perfect interpretation of engineering adaptability.

Appearance: The Mechanical Wisdom of Rock-Breaking Teeth

Mining Air-Circulation Bit (Hard Rock Type):

To withstand high impact loads, its cone design prioritizes anti-fracture principles. The cone profile is more rounded and full, with alloy teeth of lower protrusion height and relatively larger tooth tip areas. This design significantly reduces the risk of tooth tip fracture caused by stress concentration under hard rock impacts. The teeth are arranged at a moderate density to avoid breakage due to overcrowding. The bit body is thick and heavy, with wide air nozzle channels to ensure efficient high-pressure air slag discharge. The overall appearance exudes a robust and impact-resistant industrial aesthetic.

Water Well Mud-Circulation Bit (Soft to Medium-Hard Rock Type):

Aimed at formations with low shear resistance, its design core is to optimize cutting efficiency. The cone taper is flexible, with alloy teeth (or steel teeth) protruding significantly, commonly using high and narrow conical or wedge-shaped teeth. The sharp tooth edges can easily cut into soft rocks such as mudstone and sandstone, while the dense tooth arrangement facilitates rapid rock debris stripping. The overall appearance demonstrates the precise characteristics of high-efficiency cutting.

Internal Structure: The Core Battlefield of Bearings and Seals

Mining Air-Circulation Bit:

The core challenge lies in the dry and hot environment with high vibration, impact loads, and lack of lubrication and cooling. Its bearing system is extremely robust, often using large-sized "roller-ball-sliding" triple combination bearings supplemented by high-load alloy materials. Sealing is a key shortcoming, mainly relying on non-contact seals that use precise clearances to form gas flow resistance and block dust intrusion. Although fine dust cannot be completely isolated, this is a reliable choice in dry hole environments.

Water Well Mud-Circulation Bit:

The core threat is the intrusion of high-pressure mud and its abrasive solid particles into the bearing cavity. Its bearing system is also highly robust, but sealing technology is of utmost importance. It commonly employs multiple sealing barriers consisting of rubber O-ring radial seals (such as nitrile rubber and fluororubber) and metal face seals. High-quality lubricating grease is sealed within the bearing cavity to form a reliable protection. API specifications impose strict testing requirements on the sealing performance of water well bits to ensure their viability in harsh mud environments.

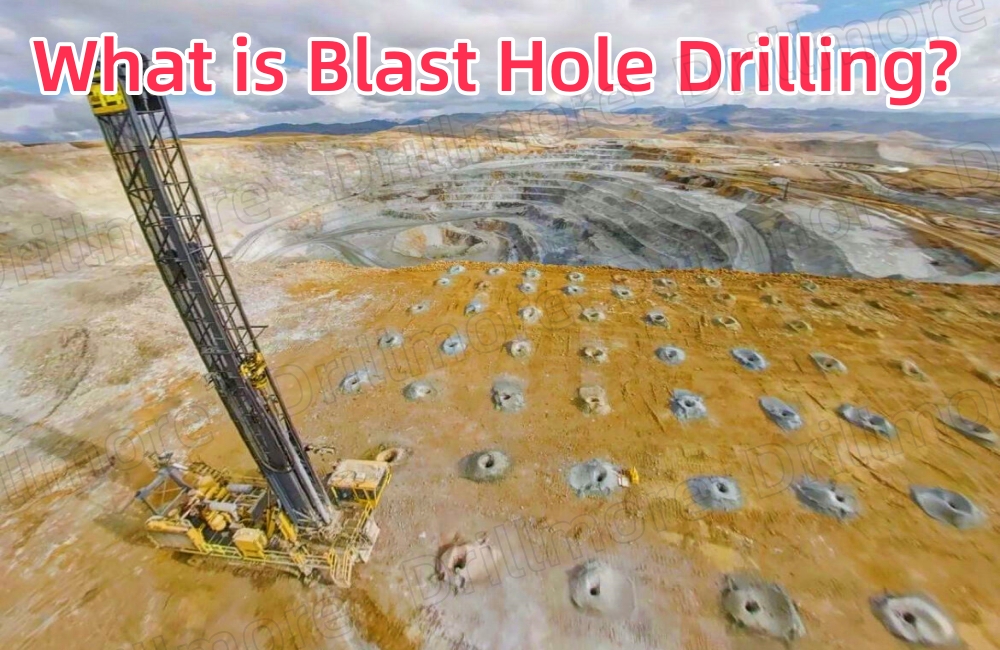

Application Environments: The Vast Chasm Between Dry and Wet, Hard and Soft

Mining Air-Circulation Bit:

Specifically designed for hard rock drilling and blasting, it is mainly used in metal mines (iron ore, copper ore, etc.) and quarries. The working environment typically involves dry holes or hard rock formations with only minimal groundwater seepage. Its advantage lies in efficient dry slag discharge using compressed air, avoiding potential contamination of ore grades by mud while creating favorable conditions for subsequent blasting.

Water Well Mud-Circulation Bit:

Designed for hydrogeological drilling and water well/geothermal well construction, it operates in strata ranging from loose sand layers, silt layers, and gravel layers to medium-hard sandstone and shale, with widespread groundwater. The core functions of mud circulation go far beyond slag discharge: it stabilizes the wellbore to prevent collapse, balances formation pressure to prevent water inflow, cools and lubricates the bit, and efficiently carries cuttings to the surface.

Operating Principles: The Synergy of Tooth Shape Design and Circulation Media

Mining Air-Circulation Bit:

Its blunt and tough tooth shape does not pursue "gnawing" but rather causes volume fragmentation (crushing + shearing) of hard rocks through enormous impact loads. The core role of high-pressure air is to instantly remove rock dust in the dry and hot environment, prevent efficiency reduction due to repeated grinding, and cool the bit. The principle emphasizes effective rock breaking and immediate slag removal in high-impact, low-lubrication environments. The smaller tooth exposure reduces single-tooth load and enhances overall impact resistance and service life.

Water Well Mud-Circulation Bit:

Its sharp and protruding conical/wedge-shaped teeth efficiently shear soft or medium-hard rock formations. Mud plays multiple roles: as a power medium, it is ejected at high speed from the nozzle to assist in hydraulic rock breaking; as a cooling and lubricating agent, it protects the bit; as a carrier, it suspends and carries cuttings upward; and as a stabilizer, it forms a mud cake to protect the wellbore and balance formation pressure. Its principle establishes a circular shield system based on high-efficiency cutting and centered on wellbore stability.

The essence of engineering wisdom lies in "tailoring solutions to specific needs". The mining air-circulation tricone bit uses blunt edges to resist impacts, relying on its blunt and tough tooth structure and high-speed air flow to break through dry and hard rock formations. In contrast, the water well mud-circulation bit pursues efficiency with sharp edges, constructing life channels in complex water-bearing strata through its sharp conical teeth and mud shield. Every refinement in their structures—from the precise balance between tooth shape impact resistance and cutting efficiency to the reinforcement of bearings and the revolution in sealing technology—represents humanity's resolute footsteps in engineering prowess toward the earth's depths. It is these meticulous differentiated designs that collectively support the grand cause of modern drilling engineering, enabling it to traverse different strata and acquire precious resources.

Your email address will not be published. Required fields are marked with *