Shin ka san abin da aikin gina na shugabanci na kwance yake?

I. Shirye-shiryen Yanar Gizo

Bayan shafin yana leveled da laka rami da aka gina tanki, shirya wa shugabancidRilling na hilling Rig.

II. Sanya matsayin hawan hako

III. Rike mai shigowa

Rigning Rig Drills a cikin yashi ko yadin yadudduka. A lokacin yin hako, ya kamata ci gaba a hanzari mai sauri, da kuma sarrafa ƙarfin hakoma da shugabanci. Sashe na Shiga da Fita na fita ya zama madaidaiciya hering, tare da madaidaiciyar tsayi yana iya sarrafawa gwargwado a kusan mita 20.

Haske na gefen tsawan tsinkayefasalin:

1. Tsallake jagora: sanye take da tsarin kyautatawa tsarin (kamar saitin geomagnitic, gyroscopes) don tabbatar da viorciory da rage karkacewa.

2. Ana yin daidaitawa da cigaban cigaban.

3. Tsarukan ƙarfin iko: Rakin yana ba da santsi mai santsi da torque fitarwa don kauce wa karkatar da yanayin lalacewa ta hanyar aiki a lokacin yin hakowa.

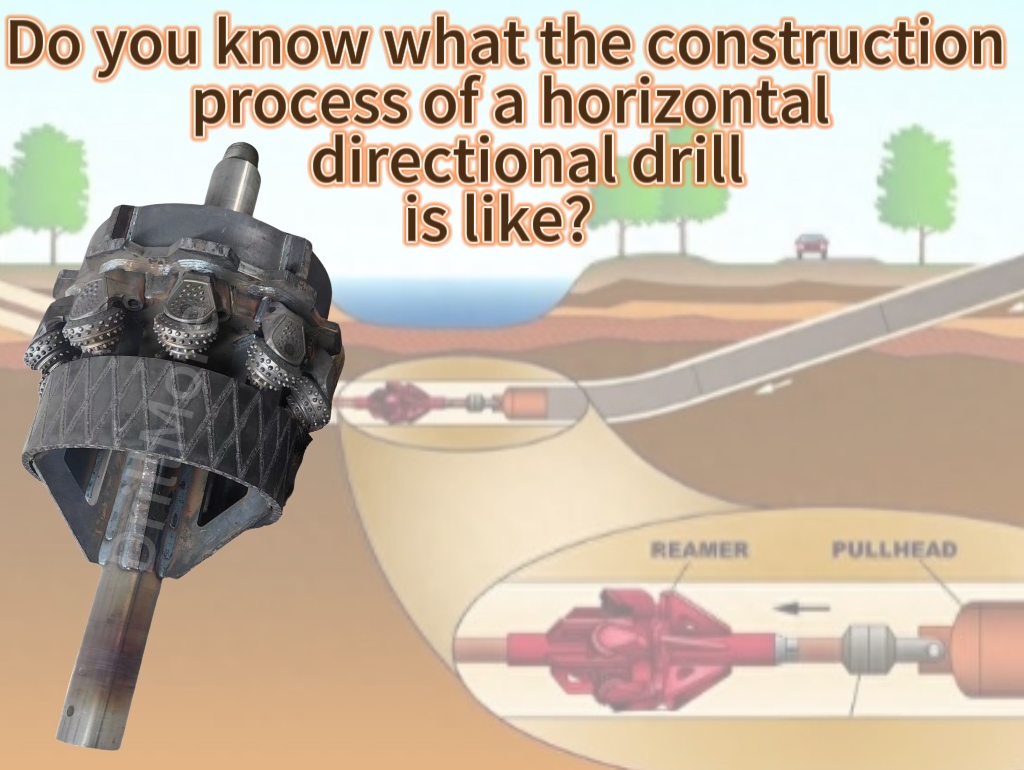

IV. Maimaitawa

Bayan rawar soja ya fice daga matsayin manufa, maye gurbinsa da mafi girmarawar soja. A lokacin sake fasalin da dawowa-sake komawa, ja bututun ciki don kammala kwanciya. Reaming should be completed in one or multiple times according to conditions such as the medium hole diameter, pipeline area radius, soil layer conditions, and equipment capacity. Mafi mahimmancin ma'anar wannan fasaha shine ikon farko na bit bit a karkashin kasa. Tun da yake wajibi ne don motsawa daga aya zuwa aya B tare da tsara Route, bututun rawar soja dole ne ya ci gaba da kyau a karkashin ƙasa yayin guje wa sauran bangaren ƙasa, kamar manholes da sauran bututun ruwa. Sabili da haka, an shigar da firikwensin a ciki, wanda ainihin lokaci yana watsa bayani kamar kusurwa bit ɗin, da kuma tura kwari na gaba, kuma yana tura bututu mai fiɗa gaba ɗaya, kuma yana tura bututu mai iska gabaɗaya, don haka bit ɗin rawar soja gaba, kuma don haka bit ɗin rawar soja ya motsa zuwa sama. Wannan ka'ida ya shafi hagu ko kuma ragi. A ƙarshe, injiniyoyi za su jagorantar da bit bit don fita daga rami pre-dug bisa zurfin sa da kusurwa.

Haske na gefen tsawan tsinkayefasalin:

1. Mai ƙarfi-ƙarfi Reamer: Reamer an yi shi da ƙarfi-ƙarfi, mai jure tasiri da sutura ko ƙasa mai wuya don tabbatar da rami mai ƙarfi.

2. Babban Slag Slag Exfulce: sanye take da tsarin yaduwa na laka don cire kayan maye, a cikin rami daga cikin ingancin tsayayye, da ke guje wa suttura.

3. Gudanar da karfi tsakanin hakoma da sake fasalin: Tsarin ikon sarrafa hoto na iya dacewa da girman mai sake zuwa don tabbatar da tsayayyen Torque da tashin hankali yayin sake, rushe hadarin ramin.

V. Pipeline Backhaul

Bayan an gama sake fasalin, aiwatar da bututun fasali. A wannan lokacin, Swivel da sake maimaita rawar soja ... kafin goyag da baya, tsaftace ramin don cire rami na laka a cikin rami bayan sake yin sake. Backhaul ya ci gaba ci gaba daga batun fita zuwa wurin shigarwa, ta amfani da uniform da jinkirin jan hanyar. An hana jan hankali. Bayan bututun mai baya ya kammala, tsaftace shafin ginin don kammala aikin.

Haske na gefen tsawan tsinkayesiffa

1.Pipline Backhaul resistance, da kuma fitar da karfin gwiwa yana da iko daidai don gujewa lalacewar bututun mai da aka haifar ta hanyar tashin hankali nan da nan.

2. Tsarin kariya na bututun mai: Tsarin laka na laka: Tsarin laka na laka yana da inganci yayin tallafawa don rage tashin hankali tsakanin bututun mai da aka yi, yayin da aka samar da kayan aikin da ke tattare da kayan tashin hankali don daidaita saurin baya a ainihin lokaci.

3. Dokar kayan aiki: tsarin hydraulic da kuma kayan aikin watsa da suna da kyakkyawan secking aikin don gujewa gazawar bayan gida kuma tabbatar da nasarar baya-lokaci.

Wannan fa'idar bututun mai yana taka muhimmiyar rawa a cikin aikin birane na zamani saboda ƙarancin lalacewa, kuma yanzu an yaba sosai.

Ba za a buga adireshin imel ɗinku ba. Alamar da ake buƙata ana alama tare da *